- Research and Development

- 2025.06.30

Behind the Scenes: Developing Innovative and Eco-Friendly In-Mold Coating Technology for the Automotive Industry

The automotive sector is working to reduce its environmental footprint and advance the Sustainable Development Goals (SDGs). In the production of auto parts, studies show that streamlining the coating stage offers the greatest potential for reducing CO₂ emissions. This realization led us to revisit conventional coating methods and launch our in-mold coating technology project. Inspired to deliver fresh innovation during this once-in-a-century industry transformation, we embarked on an ambitious development journey. In this feature, we explore the challenges our development and sales teams faced, and the pivotal roles they played, in bringing this breakthrough to life.

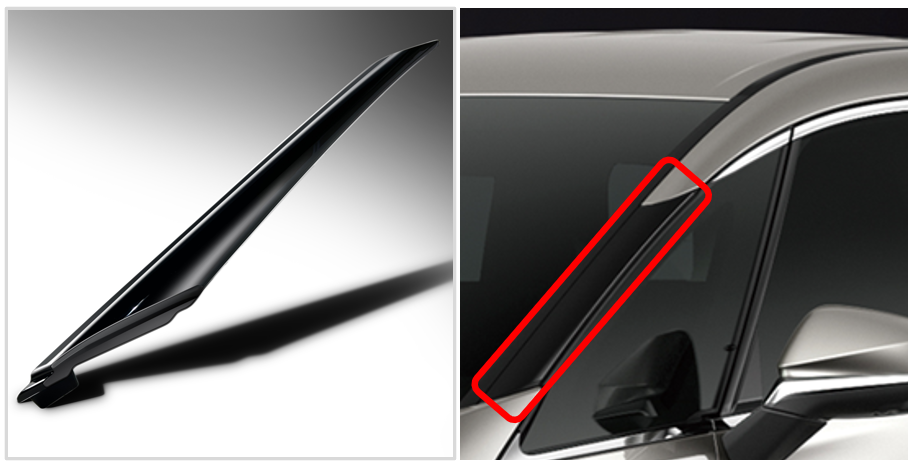

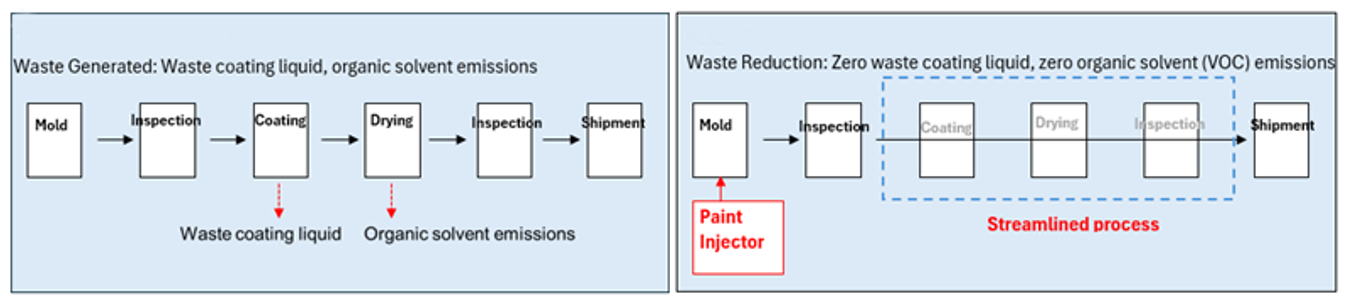

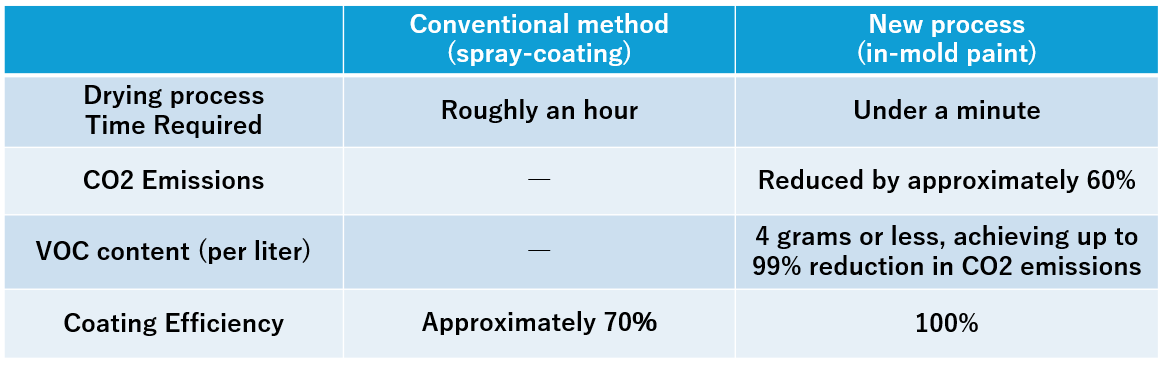

Significant CO2 Reduction Through a One-Step Molding and Coating ProcessNippon Paint Automotive Coatings Co., Ltd. (NPAC) and Uchihamakasei Co., Ltd. (Uchihamakasei), a leading supplier of exterior automotive parts, have co-created an in-mold coating technology that fuses resin molding and surface finishing into one seamless operation. By injecting paint directly into the mold during part formation, multiple downstream painting steps are eliminated, significantly reducing production time and CO2 emissions. To support the process, NPAC engineered a solvent-free formulation that contains virtually no volatile organic compounds (VOCs), delivering the same high-grade appearance and durability as conventional coatings while dramatically improving environmental performance. The result is a cleaner, more efficient manufacturing route that sets a new benchmark for sustainable automotive production.

(Left: Traditional coating/Right: In-mold coating)

(located on both sides of the windshield)

Development Began with a Ground-Up Redesign

Work on the in-mold coating formulation started in 2018, requiring a full reconsideration of every design parameter since the concept differed fundamentally from conventional paints. The team’s first priority was to create a solvent-free coating capable of curing inside the mold, while optimizing its physical properties to meet the required customer specifications. Progress was far from straightforward. The pool of raw materials suited to solvent-free formulations proved limited, adding layers of complexity to each design iteration. “Through countless rounds of trial and error, and frequent trips to an external test lab over nearly two years, we steadily refined the formulation until it met every specification,” recalls one development engineer.

NPAC and Uchihamakasei have long collaborated on spray-applied finishes. Their partnership grew from a shared ambition not only to elevate the look of molded parts but also to pioneer coating methods that advance carbon-neutral manufacturing. This common vision laid the groundwork for their latest joint effort. The outcome is Japan’s first in-mold coating system engineered for large thermoplastic resin components, materials that soften when heated, harden when cooled, and offer a combination of light weight, durability, and strength. As a result, they are widely used in automotive body panels for their fuel-efficiency benefits."

Paints used in in-mold coating must remain fluid long enough to flow evenly through the mold’s cavities, yet cure quickly once filling is complete. With small molds, this sequence is relatively simple because coating finishes quickly. As mold size increases, however, controlling paint viscosity and operating the injection equipment become markedly more difficult. A development team member explains, “Adjusting the paint formulation is essential, but some equipment challenges are beyond what a coatings maker can resolve alone. We partnered with Uchihamakasei to tackle those issues. By drawing on their injection-molding expertise and fine-tuning both the mold design and the paint-delivery system, we have moved one step closer to fully establishing this technology.”

Another Major Hurdle: Real-World Weathering TestsOutdoor weathering presented yet another critical challenge. Exterior automotive parts must meet extremely high durability standards, requiring multi-year exposure to natural elements to assess actual aging and degradation. To speed up development, we relied on accelerated weathering testers that simulate conditions such as sunlight, wind, and rain in a controlled environment. Early progress was promising, lab test results met key benchmarks, and development moved forward accordingly. However, the results from long-term outdoor exposure tests told a different story. They fell short of expectations, revealing just how demanding real-world environmental conditions can be.

To pinpoint evaluation methods that truly mirror outdoor conditions, we compared weathering protocols and specifications used in Japan and overseas. This review led us to an approach whose results aligned most closely with real-world exposure, allowing us to run natural-weathering and accelerated tests in parallel. “Determined to shorten lead times, we switched from ocean freight to air-shipping samples to Okinawa for exposure trials,” recalls one engineer. “Each shipment brought a mix of optimism and setback, and we refined our process through constant trial and error.” Because surface appearance alone can mask early deterioration, we also performed detailed micro-level analyses. These data helped us trace probable degradation mechanisms and iteratively adjust the formulation. By confronting each obstacle together, the team advanced methodically until performance targets were met.

Alongside formulation and design work, we fine-tuned key process conditions, most notably drying time and cure temperature. At every step we partnered closely with Uchihamakasei and kept an open channel with automakers, our end customers, running iterative exposure tests until the ideal settings emerged. “We might have struggled to succeed on our own, but our strong partnership with Uchihamakasei, built on mutual trust and a constructive sense of urgency, enabled us to overcome each hurdle,” recalls a member of the sales team. “Both companies shared an unwavering resolve to see the project through. By exchanging know-how and maintaining constant dialogue with the automakers, we steered the coating through the toughest trials.”

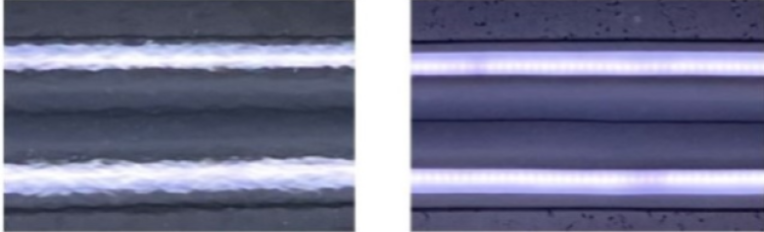

In-mold coating captures even the finest patterns etched into the mold, enabling design effects unattainable with conventional paint lines. The process also yields a surface smoothness that outperforms standard spray techniques. “Our solvent-free chemistry slashes VOC emissions, one of our biggest competitive edges,” notes a development engineer. “The coating not only satisfies the stringent standards for exterior parts but has cleared even tougher qualification tests as a brand-new technology.” The advantages extend well beyond appearance. By eliminating paint booths and bake ovens, the method cuts both CO₂ emissions and utility costs while freeing valuable floor space. Drying, which takes roughly an hour in a traditional line, is completed inside the mold in under a minute. Success hinged on an integrated strategy that optimized paint formulation and molding conditions in tandem.

Iridescent coloring is achieved without pigments by utilizing

nano-level surface structures and the interference of light

(Left: Spray Coating / Right: In-Mold Coating)

Highlighting the Unique Value of In-Mold Coating

Looking ahead, one sales team member shared the following perspective: “Our immediate goal is to expand the adoption of in-mold coated parts. I’m motivated each day by the desire to see the technology we’ve helped develop featured on actual vehicles. We will continue to showcase the distinct beauty and design freedom that only in-mold coating can offer, while clearly communicating its unique value. I believe that as more customers recognize its environmental advantages, this technology will also gain recognition as a meaningful contribution to corporate social responsibility.” On future developments, the team member added: “At present, we’re focused on large black exterior components, but we’re also working toward offering a broader range of color options.” With mass production of in-mold coated parts now underway, we remain committed to advancing this next-generation technology, driving innovation in automotive manufacturing.

For more information on our in-mold coating technology, please see here

Contributing to Carbon Neutrality: In-Mold Coating Technology in Automotive Manufacturing