- Global

- 2025.09.05

Behind the Scenes: 30 Years as a Long-Seller — The Oil-Repellent Coating That Fights Grease Buildup on Kitchen Range Hoods

Built on Trust: The Enduring Success of “Powdux Kino 2”

Powdux Kino 2, our advanced oil-repellent powder coating, was first developed in 1996 to meet the specific needs of a long-term customer in the range hood market. A member of our R&D team, who has continued refining this technology throughout its evolution, explains: “It was our proven track record with earlier powder coatings, such as Powdux P60 and P100, that led the customer to approach us for a new oil-repellent solution. The product was developed collaboratively, and we’ve been supplying it ever since, for nearly 30 years now. I believe the strength of this enduring partnership lies in the trust we’ve built through a stable, responsive supply chain that adapts to demand fluctuations, and our ability to respond quickly whenever any challenges arise in the customer’s coating process.”

Evolving Alongside Changing Lifestyles

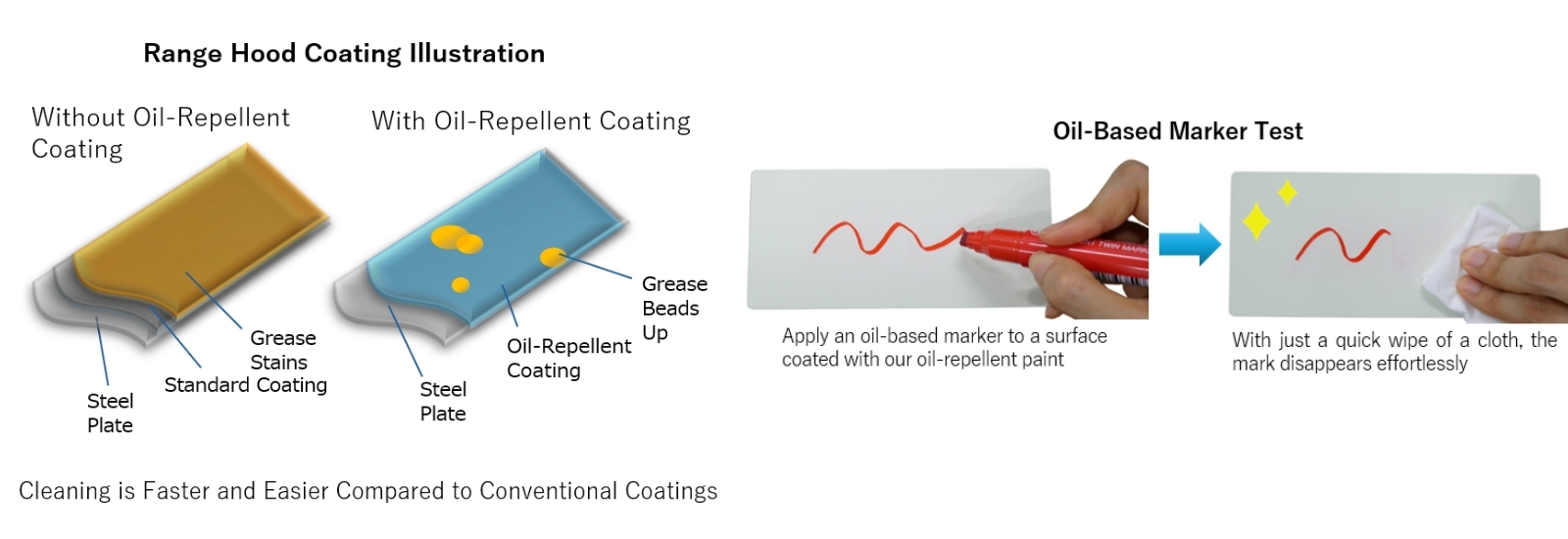

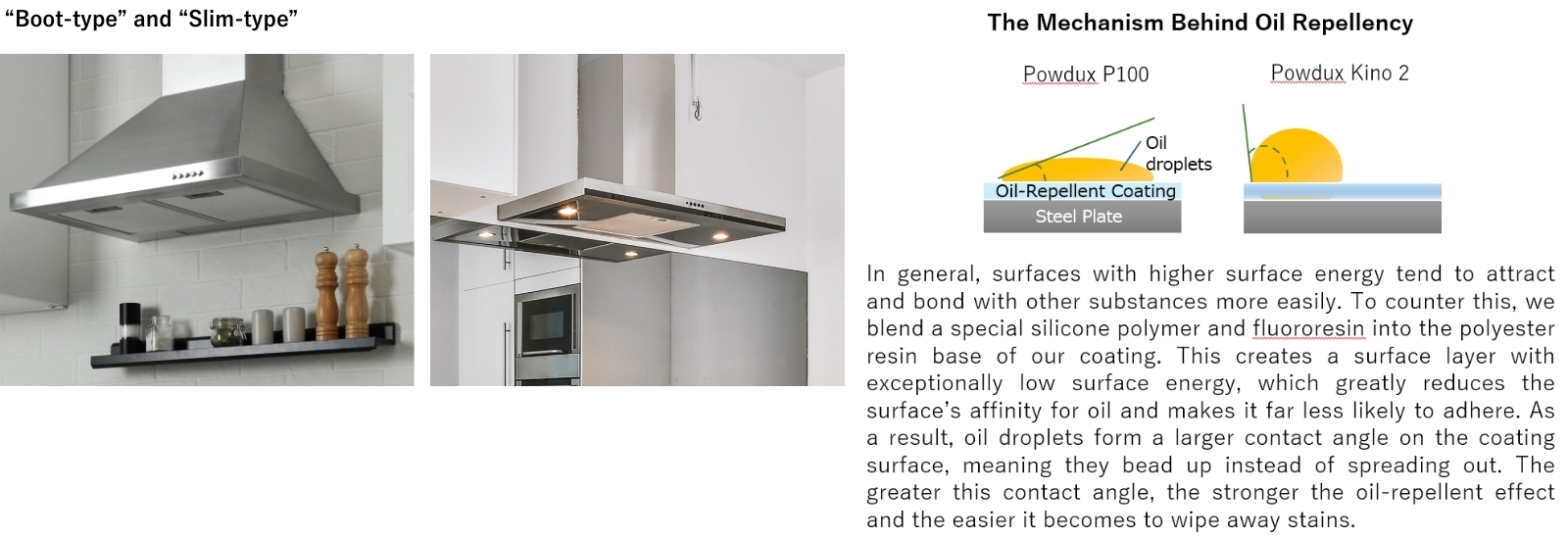

Ventilation equipment first began gaining popularity in Japan over 90 years ago. Initially known as “exhaust fans,” these devices were primarily used in factories and large buildings. From the 1950s onward, ventilation systems gradually made their way into ordinary homes. Today, range hoods have become an essential part of daily life, installed above kitchen stoves to keep indoor air clean, fresh, and comfortable. Developed by our group company, Powdux Kino 2 is now widely used in kitchen range hoods. While our conventional coatings, Powdux P60 and P100, are valued for their oil-repellent properties that help reduce grease buildup, Powdux Kino 2 takes convenience a step further by offering enhanced ease of cleaning. Even dried oil stains can be effortlessly wiped away with a simple cloth, making kitchen maintenance simpler than ever. One of our developers explains: “Range hoods are constantly exposed to heat, which causes grease and stains to dry and adhere stubbornly to the surface. To tackle this, we blended a special silicone polymer and fluororesin into the polyester resin base of our coatings. This creates a protective layer that repels oil and makes cleaning significantly easier. It works in much the same way as non-stick frying pans treated with fluororesin, preventing food from sticking and simplifying maintenance. That’s exactly why we add fluororesin into our oil-repellent coatings.”

Meeting Diverse Design Needs

Beginning in the 2000s, more customers started incorporating their personal color preferences into kitchen décor. In response, the range of coating colors for range hoods expanded beyond the traditional white and black to include a variety of vibrant options, such as red, blue, and silver. At the same time, range hood designs have evolved to reflect modern lifestyles and interior trends. Popular styles today include the Boot-type, with its narrow top and wider base; the Slim-type, an inverted T-shape favored in recent models for its sleek, modern aesthetic; and the Flat-type, a compact variation of the Boot-type featuring a flatter, minimalist profile. A member of our R&D team explains: “As range hood shapes have become more complex, achieving uniform coating coverage, especially in inner areas, has become increasingly challenging. To address this, we developed a new coating formulation with finer particles that ensures even application. This innovation has since become an industry standard.”

Beyond design and aesthetics, ease of maintenance is now a key requirement for modern range hoods. The R&D team member adds: “With vertical or sloped designs, stains naturally accumulate in specific areas, making cleaning relatively simple. However, flat surfaces pose a different challenge. To prevent stubborn grease buildup, we focused on reducing the affinity between the coating surface and oil. By creating a coating film with low oil adhesion, grease is far less likely to penetrate, making it much easier to wipe away stains.”

Helping Reduce Steel Waste and Enhance Durability

Powdux Kino 2 is specially engineered to combine strong oil-repellent properties with the unique ability to be repainted over dried coatings. While most standard coatings can be applied in multiple layers without difficulty, oil-repellent coatings often pose a challenge: applying a second coat can sometimes create surface defects, such as dents where the new layer pushes the previous one aside, resulting in an uneven finish. Achieving the optimal balance of silicone polymer and fluororesin within the formulation is critical to overcoming this issue. A member of our R&D team explains: “For example, if a surface flaw occurs during finishing, such as dust getting trapped in the coating, we simply polish the affected area and repaint the entire surface. Without this capability, the steel substrate would need to be discarded. The ability to recoat without complications helps reduce steel resource losses.”

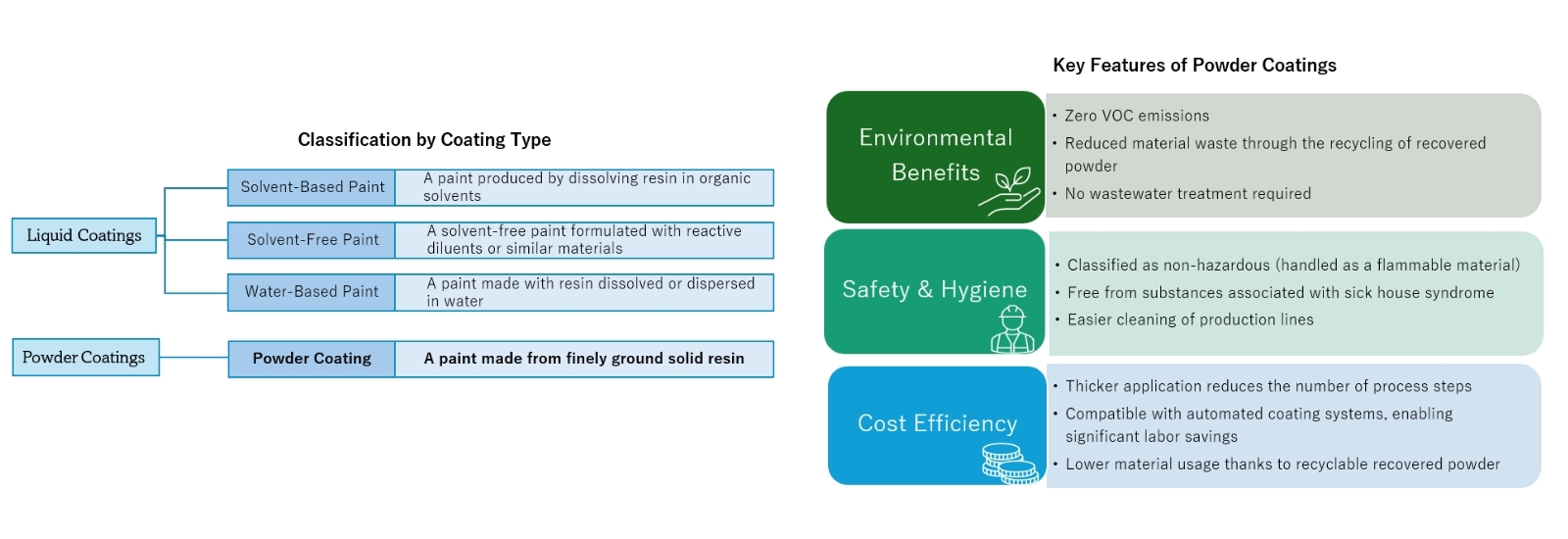

Another distinguishing feature of Powdux Kino 2 is that it is a powder coating. As one of our R&D team members explains: “Most people tend to think of paint as a liquid, but there are also coatings created by melting, mixing, and grinding solid resins and pigments into fine particles. These particles are then applied as a powder coating, which is considered ideal, especially from the perspective of reducing VOCs (Volatile Organic Compounds).” Traditionally, range hoods were often designed in a horizontal U-shape, with three sides enclosing the cooking area. Applying liquid coatings evenly to these corners was challenging, as drips and uneven finishes were common, requiring considerable skill to achieve a smooth, uniform surface. Over time, manufacturers increasingly switched to powder coatings, and with good reason. Unlike liquid paints, which typically produce a 20–40μm thick film (1μm = 1/1000mm), powder coatings can form a robust 50–100μm layer in a single application. The result is a thicker, more durable, and resilient finish.

Rapid On-Site Response to Challenges

Occasionally, when powder coating is applied on a customer’s manufacturing line, coarse particles may be ejected, resulting in surface lumps. A member of our sales team explains: “Whenever an issue arises, we make it a priority to visit the site immediately and provide an effective solution. This responsiveness has helped us earn the trust of our customers.” Such problems are most likely to occur at the start or end of the spray coating process. The causes can vary, from temperature fluctuations that cause powder particles to clump together, to insufficient cleaning of the spray gun’s nozzle. “We’ve also worked closely with equipment manufacturers when needed to improve the yield of defect-free products,” the sales representative continues. “For example, when a customer transitioned from regular powder coating to Powdux Kino 2, we spent nearly two full days alongside their team, thoroughly cleaning tanks and paint booths to prevent any contamination. Thanks to these efforts, we successfully launched their new production line, an achievement we still look back on with pride.”

Exploring New Possibilities for Oil-Repellent Powder Coatings

Although powder coatings have a proven track record, their overall sales volume has remained relatively modest. This is partly due to challenges such as the complexity of changing colors and the need for dedicated facilities, including specialized paint booths. However, powder coatings offer significant advantages. Recovered powder can be reused, and VOC emissions are greatly reduced, making them well aligned with sustainability goals and the SDGs. Globally, stricter environmental regulations are accelerating the shift from solvent-based paints to powder coatings, with demand rising particularly rapidly in China. Leveraging these strengths, we anticipate growing interest from a diverse range of industries seeking eco-friendly, high-performance coating solutions.Expanding the market for powder coatings requires continuous innovation and a commitment to addressing new challenges. A member of our R&D team explains: “It’s essential to promote closer collaboration among researchers and strengthen partnerships that extend beyond organizational boundaries. At the same time, there is a growing need to develop coatings with advanced features, such as antibacterial properties, and to create products with greater environmental consideration. While continuing to meet current market demand, we remain committed to exploring new possibilities for oil-repellent powder coatings.” More than three decades since their introduction, these coatings continue to evolve.

Contact for Oil-Repellent Coatings:

・Nippon Paint Industrial Coatings Co., Ltd. Click here to contact us.

Research and Development