- Global

- 2025.12.18

Behind the Scenes: The Making of Danziora-An Advanced Anti-Corrosion Coating to Protect Cultural Heritage for Future Generations

Bridges, factories, and industrial plant equipment along coastlines are continuously exposed to harsh conditions, salty sea air, high humidity, and saltwater, year after year. Ensuring the long-term protection of these structures requires anti-corrosion coatings with exceptional resistance to salt damage. As society places growing emphasis on extending infrastructure service life while reducing maintenance costs, our development team set out to challenge conventional coating application methods. Guided by a new way of thinking, they pursued an innovative coating technology that delivers outstanding anti-corrosion performance through a more efficient and simplified application process. This article tells the story behind that challenge, and the creation of Danziora.

A Societal Imperative: Managing Aging Bridge Infrastructure

When rust and corrosion are left unaddressed, the structural integrity of bridges and other critical infrastructure gradually weakens, increasing the risk of partial, or even catastrophic, failure. In Japan alone, there are approximately 730,000 bridges, nearly 40% of which are now more than 50 years old. In regions exposed to especially severe environmental conditions, age-related deterioration has already become a serious and growing concern (Ministry of Land, Infrastructure, Transport and Tourism, Current Status of Aging of Infrastructure and Issues in Addressing Aging). Compounding the problem, a shortage of maintenance contractors and other practical constraints make timely intervention increasingly difficult.

The ambition to help address this pressing societal challenge through advanced protective coating technology became the starting point for the development of Danziora. “The name Danziora combines the Japanese words for ‘blocking’ (dan) and ‘salt’ (zio), reflecting our mission to protect structures from harsh, salt-laden environments. Shaped by extensive on-site feedback and continuous technological innovation, the product was created through close collaboration and intensive discussion among our development, sales, and marketing teams,” explains a member of the development team.

Collaborative Development of a Coating Applicable to Rusted Surfaces

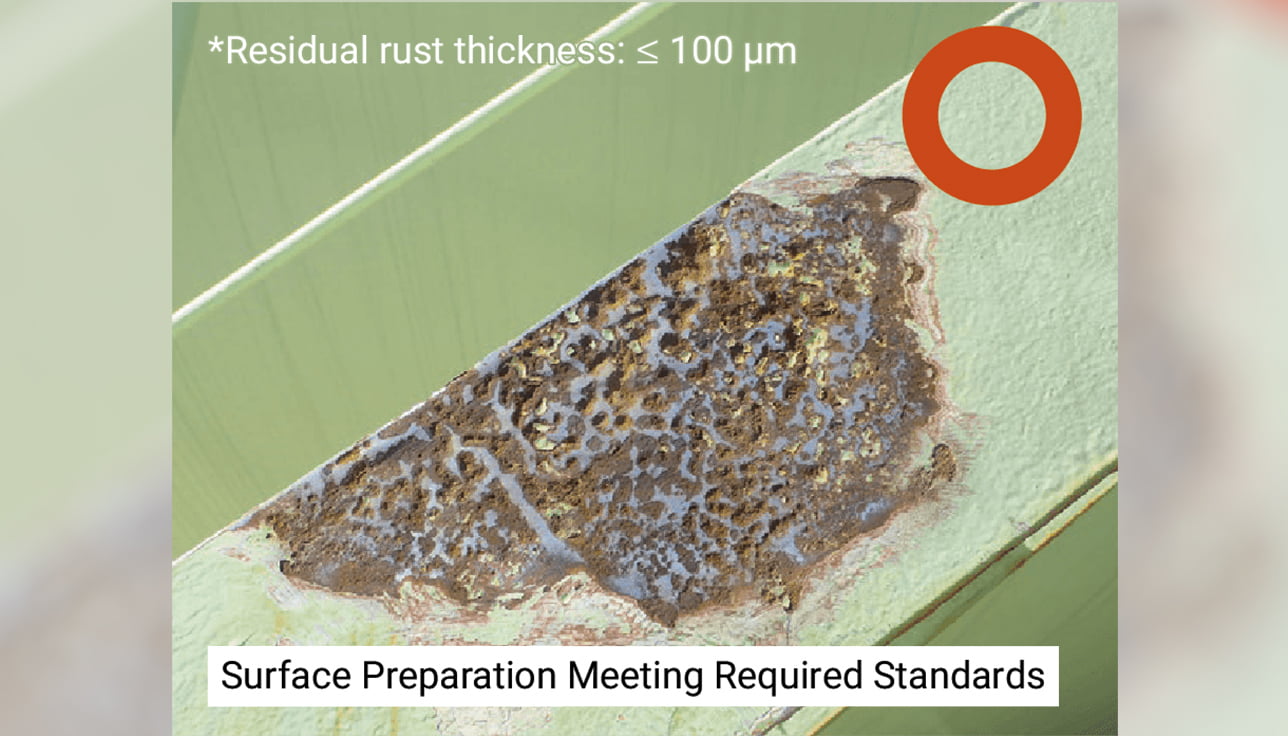

A fundamental requirement of any protective coating is strong adhesion to the underlying surface. When the substrate is contaminated, adhesion can be compromised, leading not only to premature coating failure but also to an uneven or unattractive finish. For this reason, the basic principle of coating application is to prepare the surface so the coating can spread uniformly and form a continuous, stable film, a process known as surface preparation. In practice, surface preparation typically involves removing rust using abrasives or power tools. However, when repainting bridges, factories, or plant equipment, this process becomes particularly challenging. Strict fire-safety regulations, limited working space, and operational constraints often restrict the use of conventional methods. As a result, there are situations in which coatings must be applied to substrates where some degree of rust remains.

Traditionally, when complete rust removal was not feasible, contractors had little choice but to rely on a multi-step approach. A coating with a rust-conversion function was first applied to chemically stabilize the remaining rust, followed by a separate anti-corrosion primer. No single product was able to perform all of these functions simultaneously. “Our on-site teams repeatedly told us that the number of application steps was extending project schedules and driving up costs. That feedback became a powerful catalyst for pursuing a new coating that could address these challenges in a single solution,” recalls a member of the development team. Even so, the concept was not immediately embraced within the company.

“As a coating manufacturer, we have long emphasized the importance of thorough surface preparation. Developing a product that appears to run counter to that message inevitably caused internal debate, including from a marketing perspective. At the same time, we understood that there are real-world environments where ideal surface preparation simply cannot be achieved. When large-scale rehabilitation projects begin simultaneously, labor shortages often limit the time available for rust removal. Taking these practical constraints, along with the technical hurdles, into account, we engaged in extensive discussions about whether and how to move forward with development,” explains a member of the marketing team.

Even so, responding to clear customer needs, the team resolved to pursue the development of a coating that could be applied directly to rusted surfaces without compromising anti-corrosion performance. To turn this concept into reality, they partnered with Dr. Masato Yamashita, President of Kyoto Materials Co., Ltd. and a Visiting Professor at Osaka University, an expert in the fundamental science of corrosion. With this collaboration in place, full-scale development commenced in January 2023.

A Counterintuitive Approach to Protecting Steel Structures in Salt-Exposed Environments

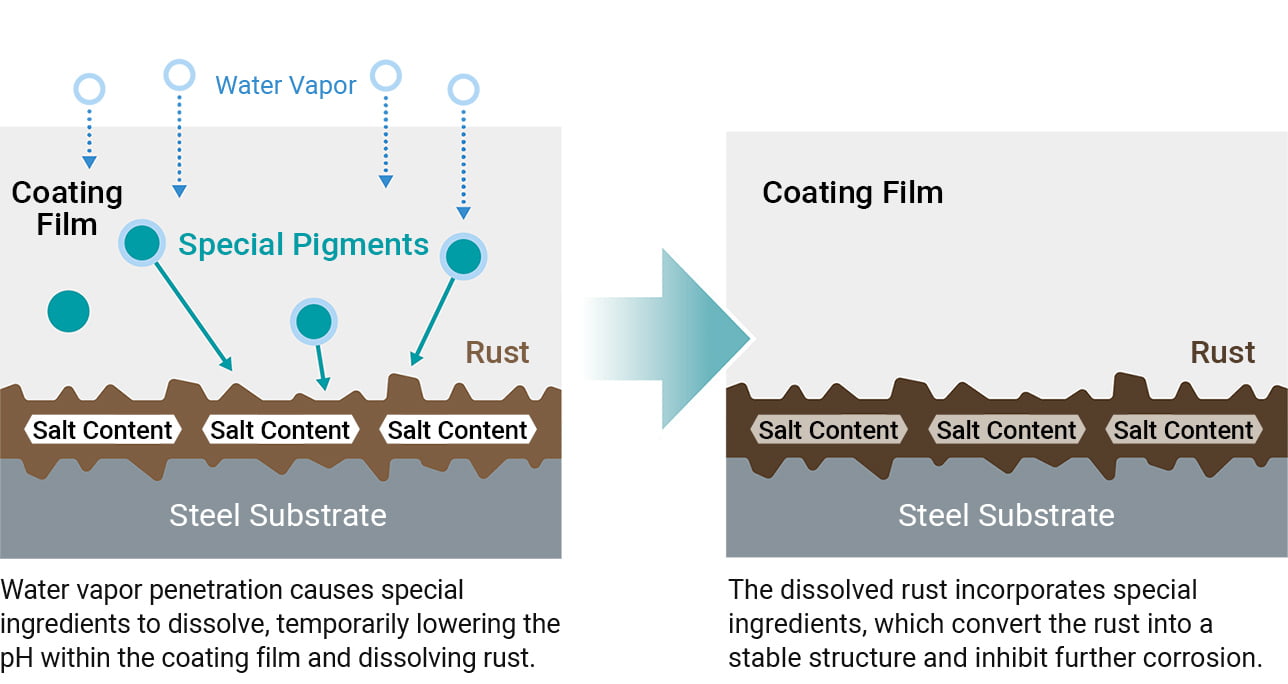

To prevent metal from corroding, its surface must be isolated from the primary drivers of corrosion, salt, oxygen, and moisture. Protective coatings are commonly used for this purpose, forming a physical barrier between the metal substrate and harsh, salt-laden environments. However, with conventional coating systems, completely blocking the permeation of water vapor is extremely difficult.

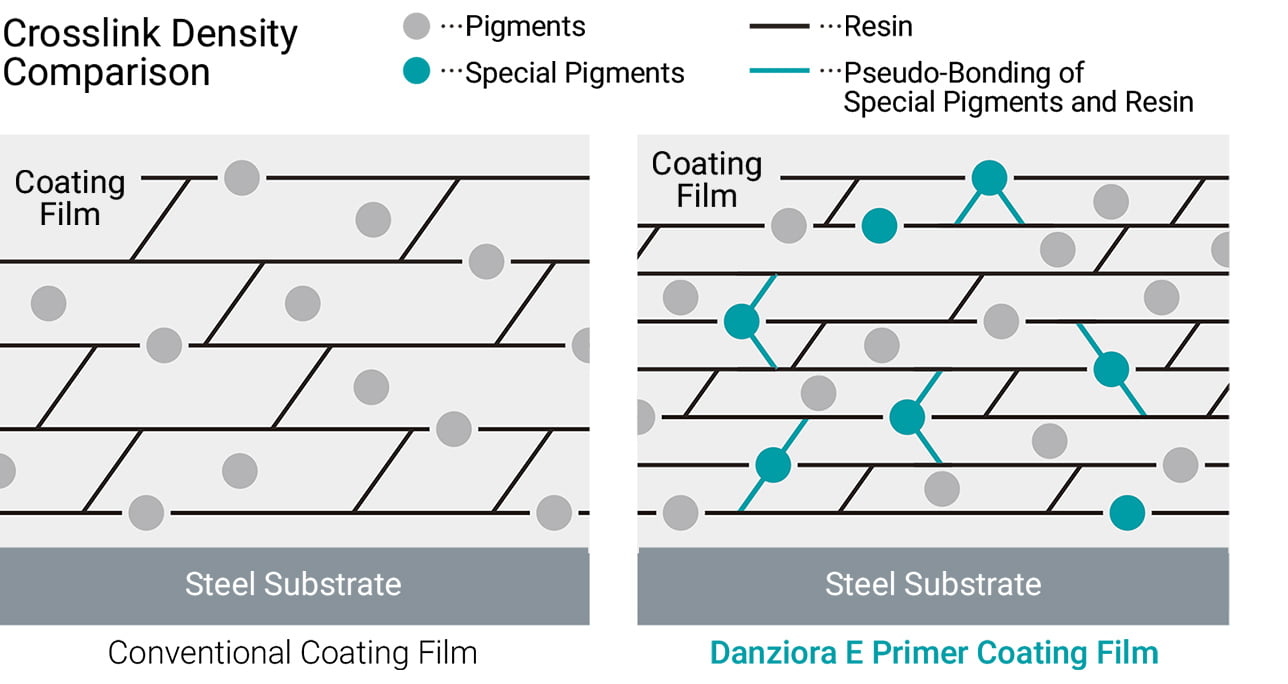

With Danziora, the development team chose to turn this inherent limitation into an advantage. As water vapor slowly permeates the coating over time, specially designed pigments within the film dissolve and form pseudo-bonds with the resin matrix. This reaction progressively creates a denser coating layer, further inhibiting the ingress of salt and oxygen. In essence, the coating is engineered to harness moisture itself, an approach that fundamentally reverses conventional corrosion-prevention thinking. This is the high-barrier mechanism behind Danziora. In parallel, the development team held extensive technical discussions with their research partner to refine the technology that enables the coating to be applied directly to rusted surfaces.

“Rust is not a single, uniform substance; there are many different types. Some forms, often referred to as ‘good rust,’ help suppress further corrosion, while others, known as ‘bad rust,’ actively accelerate the corrosion process. Under normal environmental conditions, rust tends to evolve into the latter, making it essential to intentionally convert it into a more stable, protective form. Corrosion itself is an electrochemical process in which solid materials gradually deteriorate and ultimately fail. The defining characteristic of ‘good rust’ is its low electrical conductivity. By limiting electron transfer, it effectively suppresses the corrosion reaction and significantly reduces the risk of further material degradation,” explains a member of the development team.

Elucidating Rust Mechanisms and Building the Core Technology

In rare cases, iron objects dating back more than 2,000 years have survived in remarkably good condition. By examining such examples, the team worked closely with their development partner to identify the specific conditions and substances required for rust to transform into what is known as “good rust,” and to clarify the underlying mechanisms behind this phenomenon. From there, they began exploring whether this stable, protective rust state could be intentionally reproduced through a coating.

Even after the fundamental principles were understood, translating them into a practical coating formulation proved far from straightforward. The team carried out repeated verification cycles using salt-spray testing, accelerated corrosion test equipment, and long-term outdoor exposure tests to evaluate real-world weathering performance. These test-and-review cycles were repeated approximately seven times, with results shared and discussed in detail with the development partner at each stage. Through this continuous process of testing, evaluation, and redesign, the team ultimately succeeded in establishing the ideal rust-conversion technology they had originally envisioned.

Shortening Drying Time to Accelerate Projects and Lower Costs

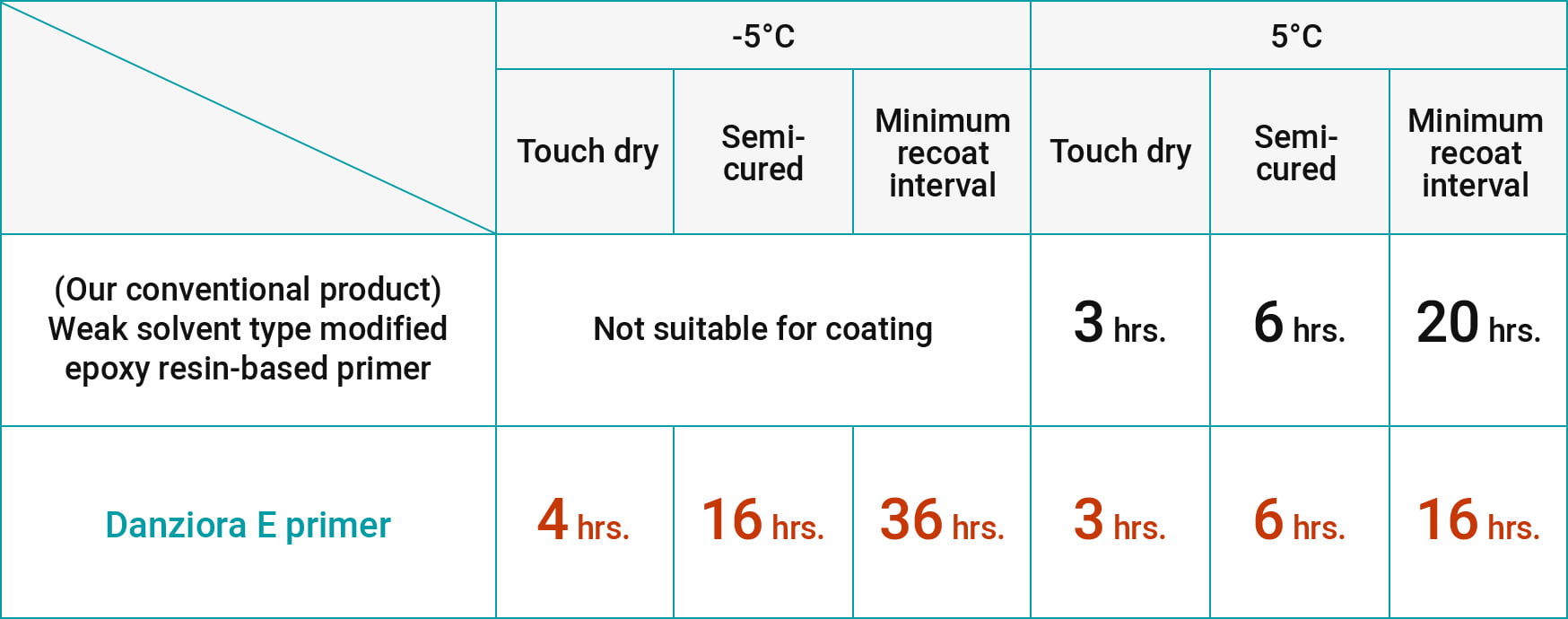

Conventional primers dry relatively quickly during summer and typically cure at ambient temperatures. In winter, however, drying rates slow significantly, particularly in colder regions, often extending project schedules and increasing downtime. “As we examined what our customers truly needed in the field, we realized that consistent, reliable drying performance throughout the year was essential,” explains a member of the development team.

Designing a coating that cures effectively at low temperatures presents a well-known technical trade-off: formulations optimized for cold conditions tend to dry more slowly under hot, ambient summer temperatures. “To overcome this challenge, the team gathered extensive field insights with support from the sales team and conducted a wide range of validation tests. These included application trials in environmental chambers at -5 °C, as well as on-site painting tests on rooftops exposed to extreme summer heat. The formulation was repeatedly refined based on these results,” adds a member of the development team.

Through this rigorous verification process, the team succeeded in designing Danziora for stable, year-round use across a wide range of climatic conditions, while minimizing inter-coat drying time. “Thanks to its excellent low-temperature curing performance, the coating continues to cure even at -5 °C, helping to shorten project schedules, reduce overall costs, and meet real on-site needs,” says a member of the sales team, highlighting the product’s advantages.

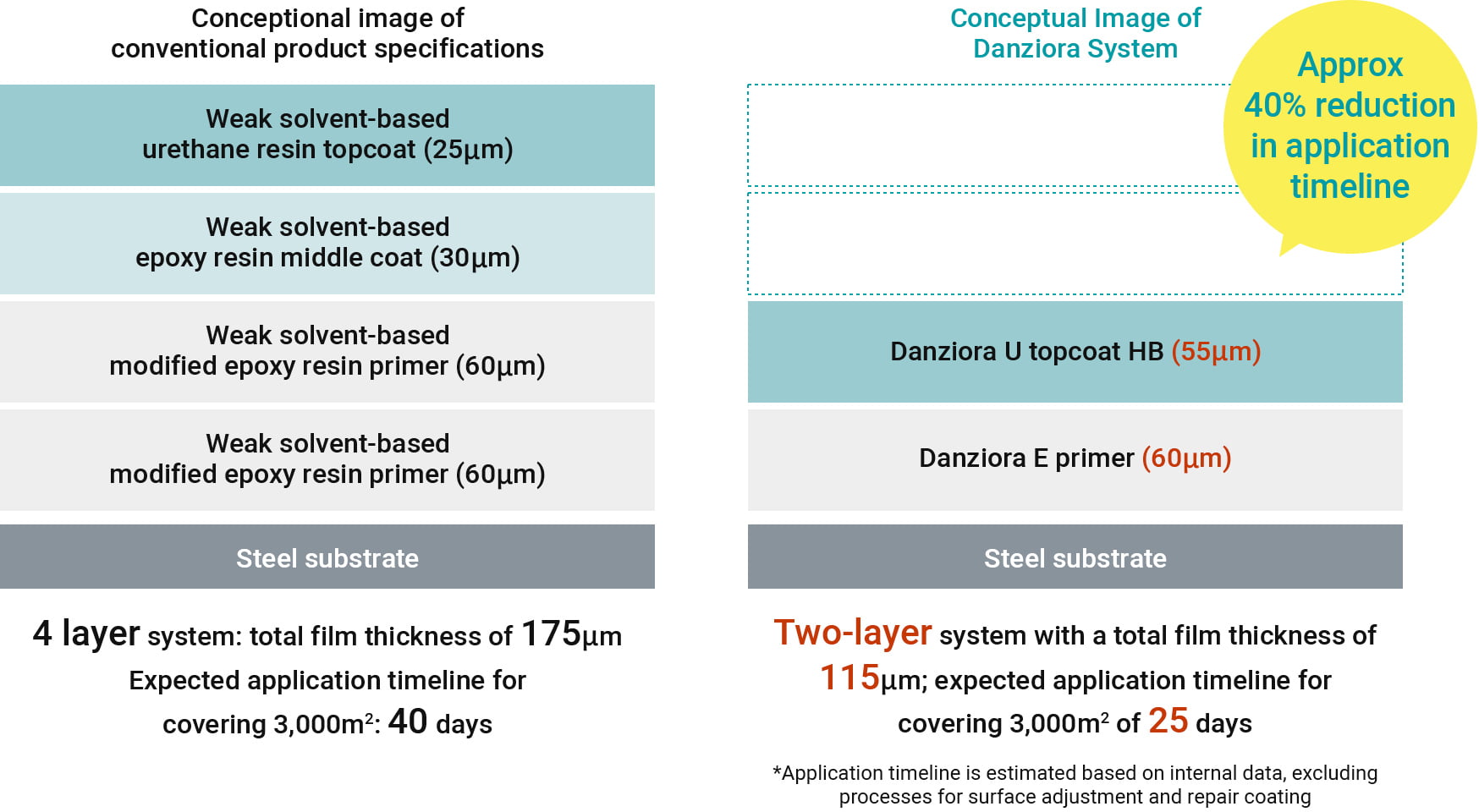

High-Performance Thin-Film Technology for Lower Environmental Impact

In salt-damage environments, effective corrosion protection has traditionally required a four-step coating process, two primer coats, one intermediate coat, and a topcoat, to block the ingress of corrosive factors. Danziora E Primer, however, delivers exceptional barrier performance, providing protection equivalent to, or exceeding, that of two conventional primer coats with just a single application. This innovation allows the primer layer, which previously required a film thickness of approximately 120 μm (1 μm = 1/1000 mm), to be reduced by half while maintaining high protective performance. Furthermore, by increasing the thickness of the topcoat, the intermediate coating step can be eliminated altogether. The result is a thinner overall coating system with fewer application steps. By reducing total film thickness and simplifying the coating process, Danziora enables shorter project schedules, lower paint consumption, and a reduced environmental impact. “We were able to eliminate more steps and reduce film thickness beyond our initial expectations. This prompted us to work closely with the development team to rapidly obtain additional physical property data, while also updating our promotional materials and videos roughly two months before launch. In the end, we successfully completed all preparations in time for the product release,” recalls a marketing team member.

Chosen to Protect the Nationally Designated Important Cultural Property, Waka-to Bridge

In January 2025, Danziora was selected for repair work on the Waka-to Bridge in Kitakyushu City, a structure designated as a National Important Cultural Property. “Public infrastructure projects such as the Waka-to Bridge must comply with fixed specifications,” explains a member of the sales team. “Danziora was highly valued because it significantly enhanced coating performance without requiring any changes to those established standards. In addition, the work was carried out in midwinter, and the fact that the coating could still be applied at -5 °C was particularly well received,” explains a sales team member.

Completed in 1962, the Waka-to Bridge is an aging structure with many extremely narrow sections, areas so confined that only a hand can fit, making complete rust removal difficult. Constant exposure to sea breezes further complicates maintenance efforts. Under these demanding conditions, Danziora’s ability to be applied directly over residual rust proved especially effective. Feedback from on-site workers was also positive, with comments such as “easy to use despite its many functions” and “dries quickly even in winter.”

“Waka-to Bridge is a highly visible landmark in Kitakyushu City, and this project has generated significant impact and strong momentum for our sales activities. While Danziora E Primer was the primary product used, our topcoat was also adopted in certain areas. Although our sales efforts are always supported by many people, winning projects that quite literally appear on the map brings the greatest sense of accomplishment. We will continue to actively promote Danziora as a nationally recognized coating technology,” adds a member of the sales team.

Product Development Driven by On-Site Feedback

Danziora is the result of close integration between on-site feedback and technological innovation. “Our guiding principle in development is to remain firmly customer-focused. We place great importance on listening carefully to voices both inside and outside the company and consistently feeding those insights back into our products,” explains a member of the development team.

“It is especially rewarding when we can hear directly from customers about the challenges they face and then deliver a solution that genuinely helps address those issues. In repainting projects for bridges and factory or plant equipment, I am confident that this easy-to-apply, long-lasting coating will contribute to safeguarding important infrastructure and cultural assets for future generations,” adds a member of the marketing team. The team remains committed to listening sincerely to on-site feedback and translating it into better products.