- Research and Development

- 2025.12.17

Toward the Development of Environmentally Friendly Coatings

Molecular-Level Simulation of Film Formation in Water-Based Paints

December 17, 2025

Nippon Paint Holdings Co., Ltd.

Toward the Development of Environmentally Friendly Coatings

Molecular-Level Simulation of Film Formation in Water-Based Paints

Key Highlights

- A research team from Nippon Paint Co., Ltd., working together with professors at the University of Tokyo’s Graduate School of Engineering, has achieved molecular-level visualization of how polymers aggregate in the solvents used for water-based coatings, and we systematically clarified how solvent composition influences polymer structure and behavior.

- In water–organic solvent binary systems, we found that phase separation triggers localized polymer aggregation, and that during solvent evaporation, the strength of polymer–solvent interactions plays a decisive role in how aggregation progresses.

- The findings obtained on polymer dispersibility and film-formation mechanisms provide valuable design guidelines for coating formulations and are expected to support the development of environmentally responsible water-based coatings.

Molecular Dynamics Analysis of Polymer Aggregation in Solvents and Over the Course of Solvent Evaporation

Molecular Dynamics Analysis of Polymer Aggregation in Solvents and Over the Course of Solvent EvaporationOverview

A research team led by Researcher Shinya Kawakami of Nippon Paint Co., Ltd., in collaboration with Assistant Professor Ryuhei Sato and Professor Yasushi Shibuta of the University of Tokyo’s Graduate School of Engineering, has systematically uncovered how polymers, the key constituents of water-based paints, aggregate within mixed water–organic solvent environments and how their structures evolve as solvents evaporate.

Using molecular dynamics (MD) simulations (Note 1), the team tracked polymer motion on a computer and directly observed their dispersion and aggregation behaviors in aqueous, organic, and mixed solvent systems. By systematically adjusting organic solvent concentration and the strength of polymer–solvent interactions, the researchers conducted an in-depth analysis of how solvents influence the earliest stages of coating film formation.

The results offer direct insights into dispersion stability and aggregation behavior in the early stages of film formation for water-based coatings, and they provide molecular-level guidelines for optimizing the design of polymer–solvent systems.

This work was published in ACS Omega, a journal of the American Chemical Society, on December 12, 2025 (local time).

Research Findings

While solvent-based coatings are still widely used across the paint industry, increasing emphasis on environmental sustainability and safety has accelerated the transition to water-based alternatives, driving steady growth in demand. In water-based coatings, polymer materials must be finely dispersed within the solvent, and as the solvent evaporates, the polymers entangle to form a durable film. However, because many polymers are not readily soluble in water, organic solvents are still required to stabilize dispersions, making their optimization a key technical challenge.

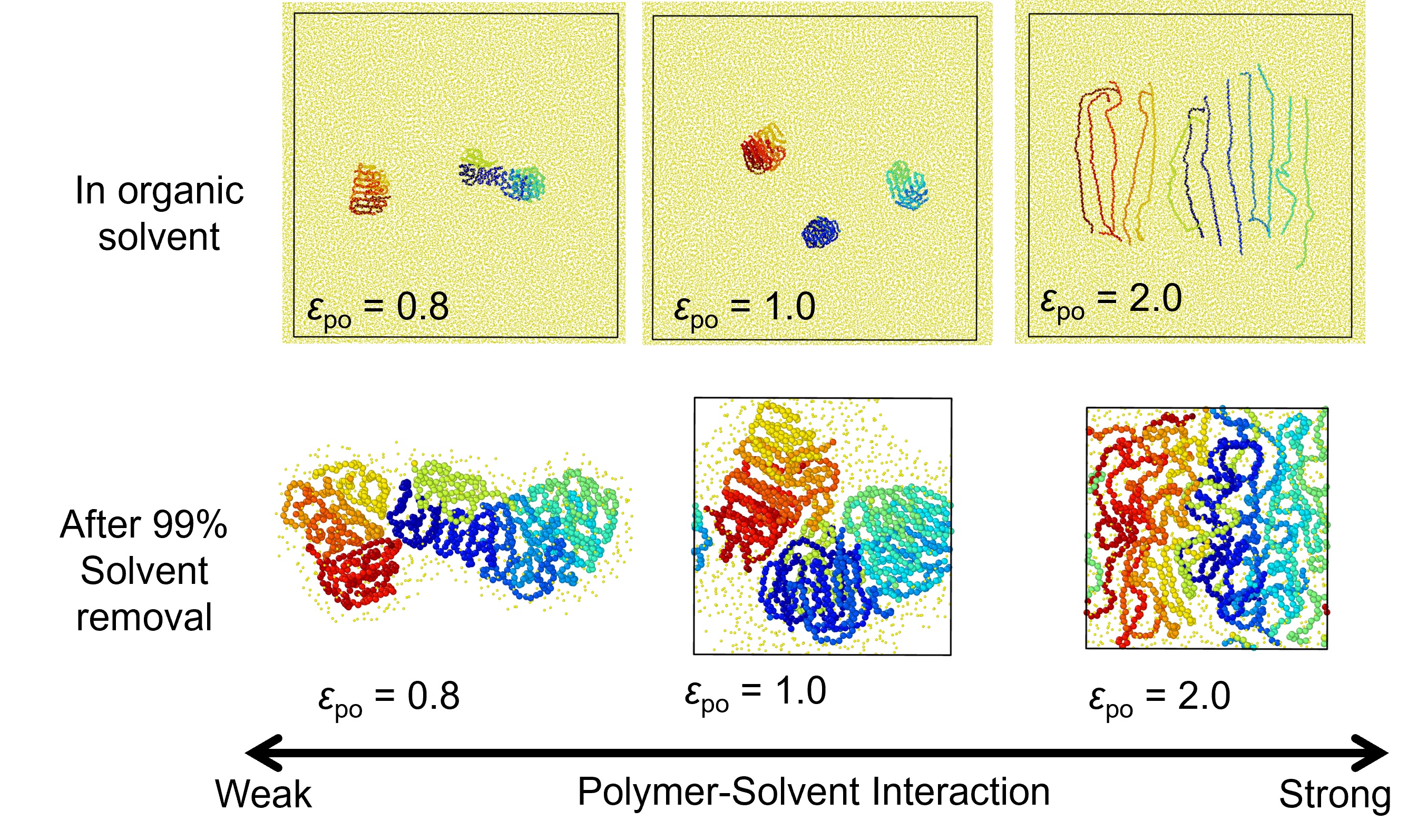

In this study, the team used molecular dynamics simulations to directly track polymer motion and compare dispersion and aggregation behavior in aqueous, organic, and mixed-solvent environments. By virtually tuning the strength of polymer–solvent interactions, the researchers systematically revealed how organic solvents influence polymer-chain conformations—whether they remain in a coiled state or begin to aggregate (Figure 1). The results show that weaker interactions lead to polymer aggregation, while stronger interactions maintain a stable dispersion.

Figure 1: Polymer Dispersion in a Single Solvent and Its State After Solvent Removal

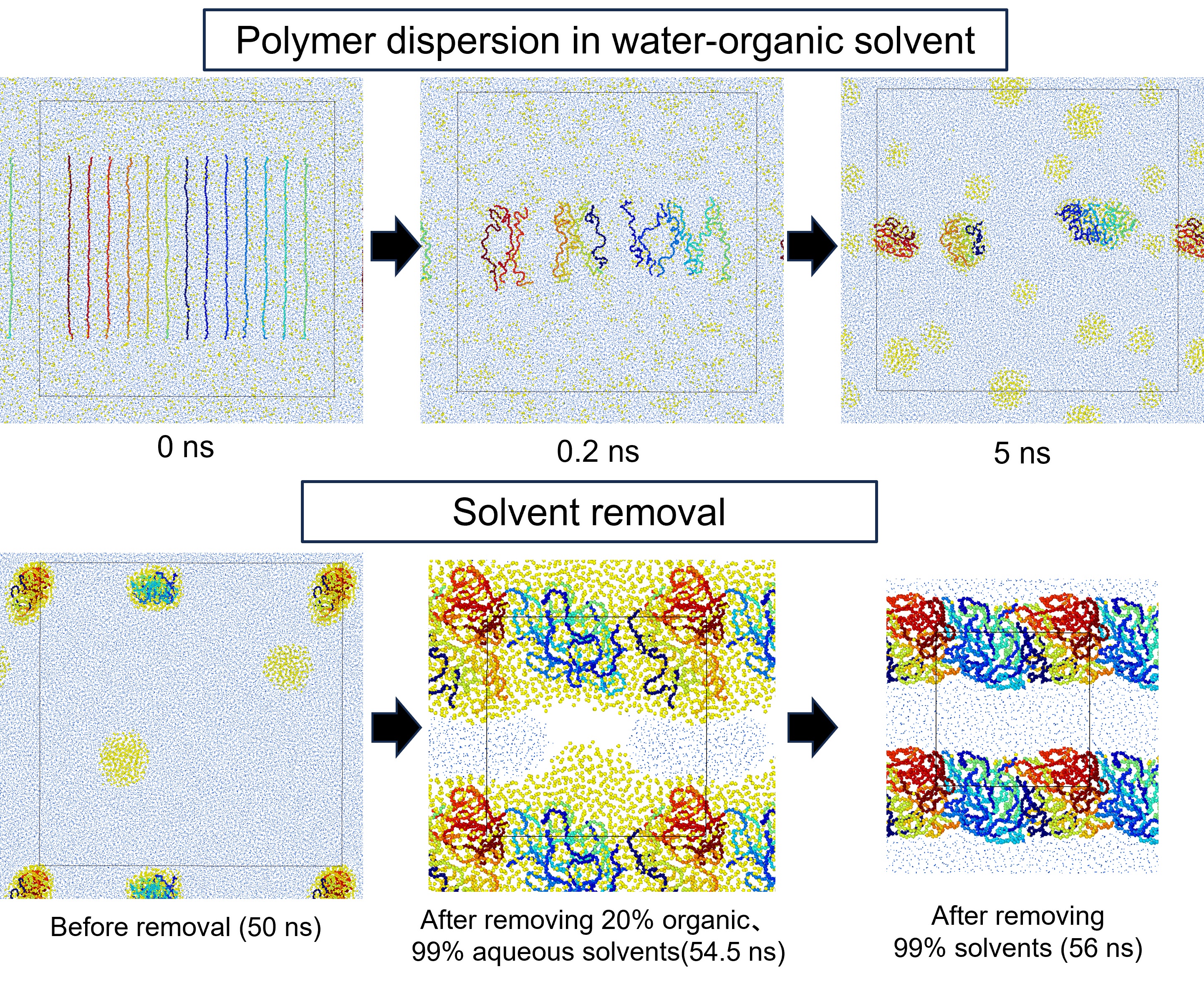

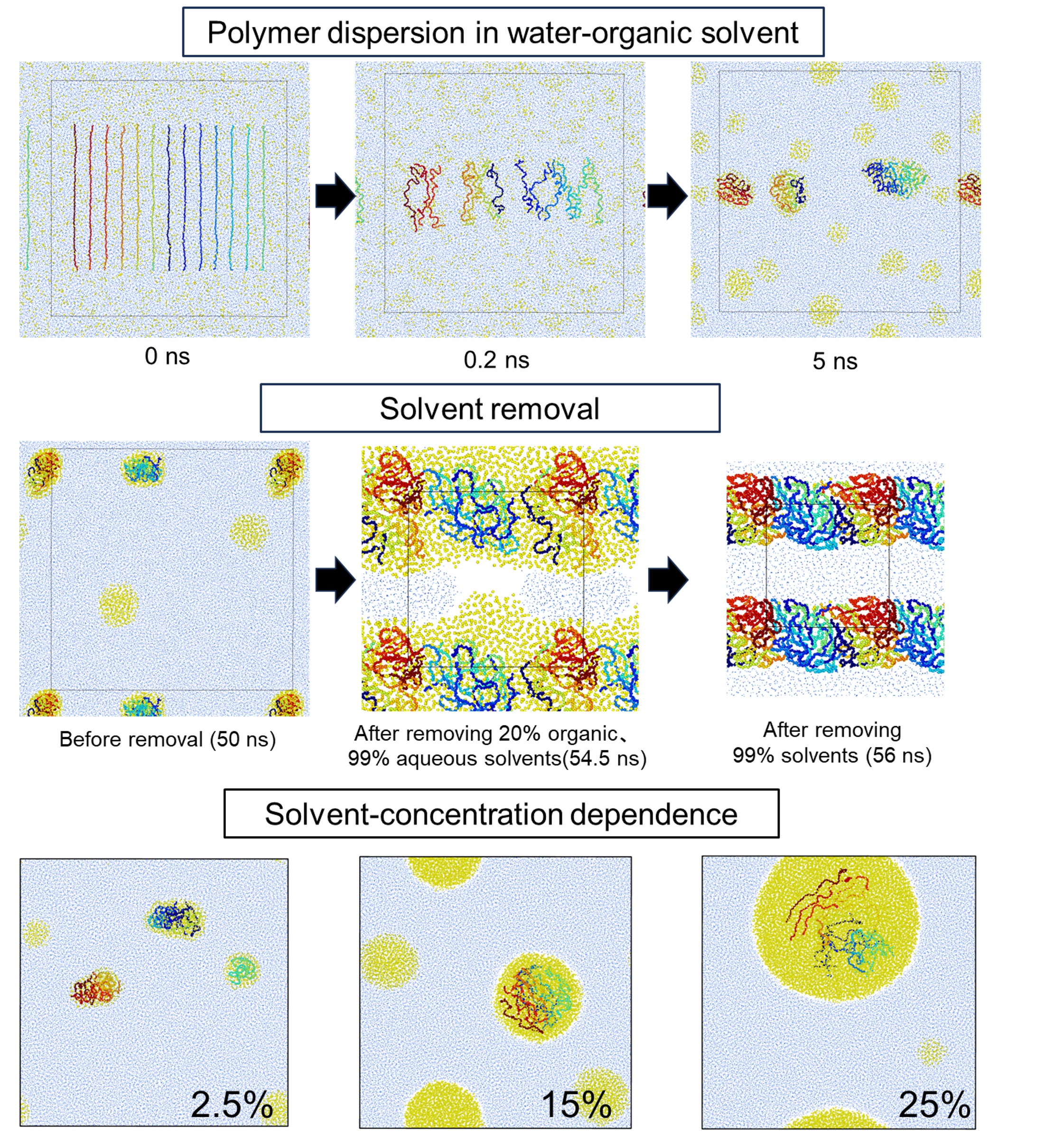

Figure 1: Polymer Dispersion in a Single Solvent and Its State After Solvent RemovalFurthermore, in mixed systems of water and organic solvents, the simulations revealed that the organic solvent undergoes phase separation within the water, forming small organic-rich domains to which the polymers locally migrate (Figure 2). The study also showed that when the proportion of organic solvent is low, polymers become confined within narrow regions, making aggregation more likely; and during solvent evaporation, the strength of polymer–solvent interactions influences the progression of film formation.

These findings directly enhance our understanding of dispersion stability and aggregation mechanisms in the early stages of film formation in water-based coatings, and they provide valuable molecular-level guidelines for designing polymer–solvent systems. This research is expected to contribute to the advancement of coating formulations aimed at reducing environmental impact through increased use of water-based technologies.

This study was conducted as a joint research project within the Social Cooperation Program “Creation of Innovative Coating Technologies” (Program Director: Professor Toru Wakihara), which was established under the industry–academia collaboration agreement between the University of Tokyo and Nippon Paint Holdings Co., Ltd.

Figure 2: Polymer Dispersion and Aggregation in Water–Organic Solvent Mixtures and the Dependence of Polymer Dispersion on Organic Solvent Concentration

Figure 2: Polymer Dispersion and Aggregation in Water–Organic Solvent Mixtures and the Dependence of Polymer Dispersion on Organic Solvent ConcentrationRelated Press Releases:

“Unraveling the Relationship Between Strength and Structure in Polymer Materials — A New Approach to Coating Development Combining Molecular Dynamics Simulations and Mathematical Science Methods” (2024/12/5)

“Toward the Development of Breakthrough Long-Lasting Coating Films — Exploring New Coating Materials Using Supercomputers” (2024/1/17)

Researchers and Affiliations

- The University of Tokyo

Graduate School of Engineering, Department of Materials Engineering- Ryuhei Sato, Assistant Professor

- Yasushi Shibuta, Professor

- Takanori Ichiki, Professor

Also: Research Director, Innovation Center of NanoMedicine, Kawasaki Institute of Industrial Promotion

- Research Center for Advanced Science and Technology (RCAST), High Performance Materials

- Hiroki Ejima, Professor

- Nippon Paint Co., Ltd., Technology Division

- Shinya Kawakami, Researcher (Advanced Product Development Group, R&D department)

- Takahiro Ujii, Researcher (Advanced Product Development Group Leader, R&D department)

- Koichi Sato, Researcher (Deputy Division Director, R&D General Manager)

Bibliographic Information

| Journal | ACS Omega |

|---|---|

| Title | Molecular Dynamics Study of Polymer Coiling in a Water–Organic Binary Solvent System |

| Authors | Shinya Kawakami, Ryuhei Sato*, Hirotaka Ejima, Takahiro Ujii, Koichi Sato, Takanori Ichiki, Yasushi Shibuta |

| DOI | 10.1021/acsomega.5c05389 |

| URL | https://doi.org/10.1021/acsomega.5c05389 |

Glossary

(Note 1) Molecular Dynamics Simulation

A computational method that tracks the motion of atoms constituting a material by solving the equations of motion. When the forces acting on each atom and their initial positions and velocities are known, the positions and velocities of all atoms at any later time can be uniquely determined.

Contact Information

For inquiries about the research

- Graduate School of Engineering, Department of Materials Engineering, The University of Tokyo

Ryuhei Sato, Assistant Professor

Tel:03-5841-7119 E-mail:r-sato@g.ecc.u-tokyo.ac.jp

- Graduate School of Engineering, Department of Materials Engineering, The University of Tokyo

Yasushi Shibuta, Professor

Tel:03-5841-7118 E-mail:shibuta@material.t.u-tokyo.ac.jp