- Sustainability

- 2025.06.27

Nippon Paint Automotive Coatings Achieves Up to 71% CO₂ Emissions Reduction at Takahama Plant Through Modal Shift

A modal shift refers to the transition of freight transport from trucks to more eco-friendly alternatives such as trains or ships. Originally promoted by the Japan Federation of Freight Industries in 2003, this initiative aims to reduce CO₂ emissions, enhance energy efficiency, and alleviate the shortage of truck drivers in the logistics industry.

At NPAC* Takahama Plant, this concept was put into action through a collaboration between the Operations Department, the freight owner, and Nippon Express Co., Ltd. Together, they shifted part of the plant’s product shipments from road to rail. As a result, the plant achieved up to approximately 71% reduction in CO₂ emissions from freight operations. This achievement has earned the Takahama Plant national recognition, including: Encouragement Prize at "the 1st Modal Shift Excellent Business Awards" and Encouragement Prize at "the 26th Logistics Environment Awards".

*Nippon Paint Automotive Coatings

Contribution of Modal Shift to Reducing Environmental Impact

As part of its commitment to sustainability, the Japan Group has set a target of achieving net zero greenhouse gas (GHG) emissions (Scope 1 and 2) by 2050. To realize this goal, group-wide initiatives are underway across operations. Starting in late 2020, our logistics team began identifying opportunities to reduce emissions across the supply chain. Building on these efforts, 2024 marked a key milestone as we expanded our focus to include Scope 3 emissions, particularly Category 4 (upstream transportation and distribution).

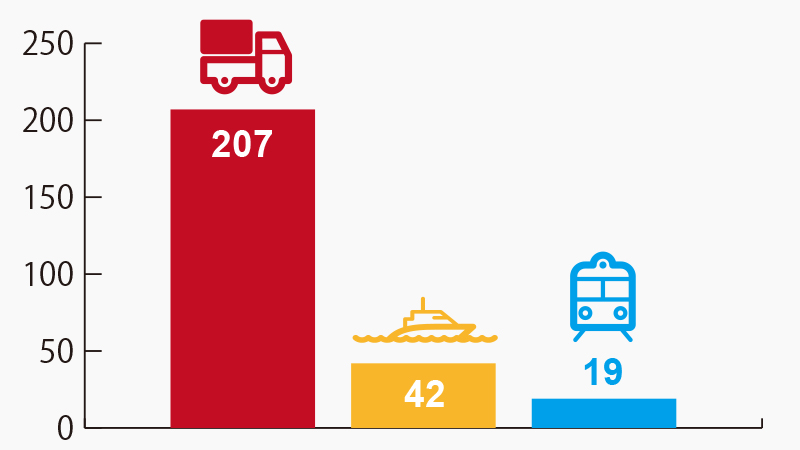

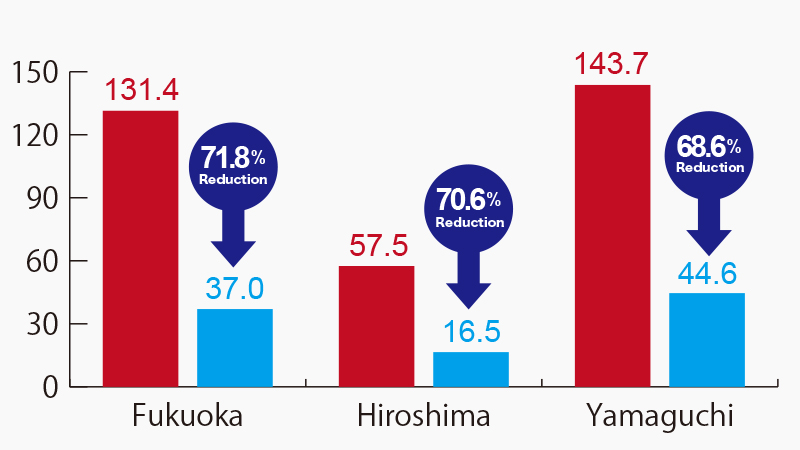

Rail freight offers a major environmental advantage over road transport, with CO₂ emissions per ton-kilometer dramatically lower. While commercial trucks emit approximately 207g-CO₂/t·km, rail transport emits only 19g-CO₂/t·km, more than ten times less. Recognizing this impact, NPAC implemented a modal shift in January 2024, transitioning shipments to Fukuoka Prefecture from truck to rail. This change resulted in a 71.8% reduction in CO₂ emissions for that route. Building on the success of our Fukuoka route, NPAC expanded its modal shift initiative in January 2025 to include shipments to Hiroshima and Yamaguchi Prefectures. These efforts led to significant reductions in CO₂ emissions: 70.6% for Hiroshima and 68.6% for Yamaguchi.

■Commercial Trucks (g-CO₂/t·km)

■Ships (g-CO₂/t·km)

■Rail (g-CO₂/t·km)

*Reference: Ministry of Land, Infrastructure, Transport and Tourism

■Before Implementation (t)

■After Implementation (t)

■Annual CO₂ Reduction Rate

The Journey from Truck to Rail

Transitioning to rail transport required careful consideration of business continuity planning (BCP), especially in the face of potential disruptions such as natural disasters, while still meeting the automotive industry's strict delivery schedules. Starting in 2020, our project team spent nearly three years working collaboratively to find the right logistics solution. After extensive discussions with multiple providers, we established a partnership with Nippon Express Co., Ltd. Their flexible proposal, built on a nationwide distribution network, offered a critical advantage: in the event of rail service disruptions, shipments could be smoothly redirected to truck transport. This strategic collaboration enabled us to successfully implement a modal shift to rail without compromising delivery performance.

With the long-term vision of transporting large volumes of paint by rail, we initiated trial shipments in 2021 using small-capacity containers. This phased approach allowed us to build operational expertise, a performance track record, and confidence in rail logistics. To enhance business continuity, we also commissioned the development of dedicated trucks designed to carry our proprietary ISO tank containers. This enabled a seamless switch between rail and road transport as needed. Over the course of three years, these efforts culminated in the creation of a robust and reliable logistics infrastructure, complete with comprehensive BCP measures.

Implementation Track Record and Future Outlook

With a solid logistics foundation in place, we successfully launched rail transport to Fukuoka Prefecture in January 2024, followed by expanded operations to Hiroshima and Yamaguchi Prefectures in January 2025. These new routes represented a significant scale-up, approximately three times the shipment volume of Fukuoka, and involved a wider range of products and multiple delivery locations, demanding meticulous coordination of loading and delivery schedules. The implementation required not only internal alignment and collaboration with logistics partners but also formal approval from our customers. To support this process, our Production, Sales, and Technology Departments worked closely to communicate the clear advantages of modal shift, such as significantly reducing CO₂ emissions, lessening the burden on truck drivers, improving scheduling flexibility through rail’s temporary storage capacity, and enhancing quality assurance by utilizing our proprietary ISO tank containers. By presenting these proven benefits and successful results, we secured the necessary approvals and established a strong foundation for ongoing rail-based logistics solutions.

With the successful launch of our first large-scale rail transport operations, we have established a strong foundation for expanding our modal shift initiatives. Looking ahead, we plan to extend these initiatives across other group companies, further advancing the Japan Group’s commitment to building a sustainable society.