- Global

- 2025.09.30

Real Voices from the Frontlines: Exploring the Cutting Edge of Innovation in FASTAR Antifouling Paint through Sales, Technical, and User Insights

Real Voices from the Frontlines Exploring the Cutting Edge of Innovation in FASTAR Antifouling Paint through Sales, Technical, and User Insights

The maritime shipping industry is under growing pressure to meet increasingly stringent environmental regulations and improve fuel efficiency. In response to these urgent challenges, FASTAR has emerged as a pioneering antifouling solution, an innovation that not only delivers exceptional performance, but also embodies a deep integration of frontline operational issues and needs, advanced technology, and the first-hand experiences of users in real-world conditions.

In this feature, we explore how FASTAR has successfully captured and addressed operational issues and needs on the ground, setting new benchmarks across the industry. Drawing on the authentic voices of a sales representative, technical engineers, and an experienced user, we offer a multifaceted look at how the insight, expertise, and dedication of professionals have fueled this innovation. Discover how Nippon Paint Marine is shaping the future of maritime performance, and sustaining its competitive edge, through innovation driven by those closest to the field.

Engineer Insights

Genki Ouchi

Nippon Paint Marine Coatings Co., Ltd.

Research & Development Department

Q1.In your view, what is the most significant innovation FASTAR has brought to the marine coatings industry?

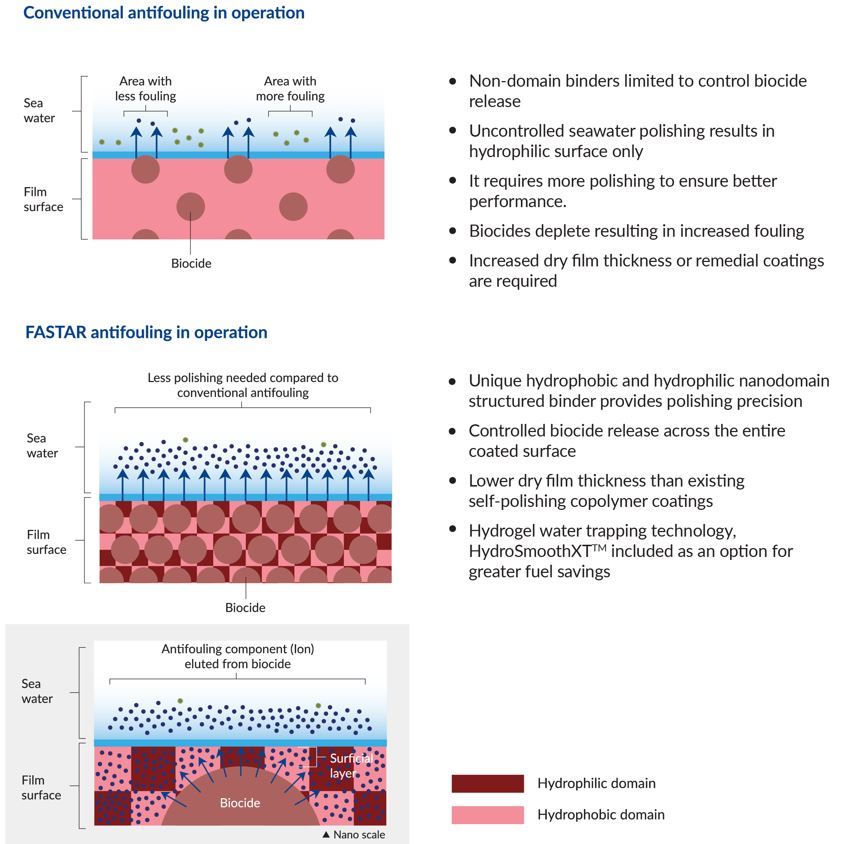

A1.The innovation brought by FASTAR goes far beyond mere performance enhancements or extensions of existing technologies. By introducing a unique hydrophilic and hydrophobic nano domain structure, FASTAR has achieved a true technological breakthrough that transcends the limitations of conventional antifouling coatings and sets a new standard in the marine coatings industry. Conventional antifouling paints rely on the continuous elution of antifouling components to provide protection as the coating film degrades through hydrolysis. However, these systems have long faced challenges in precisely controlling the polishing rate (dissolution rate of the coating film) and improving overall efficiency. FASTAR addresses these issues by incorporating hydrophilic and hydrophobic nano domain structures within the coating film, allowing for precise, nano-level control over the retention and diffusion of antifouling agents. This enables the steady and efficient release of antifouling agents over time.

As a result of its innovative design, FASTAR delivers high antifouling performance while significantly minimizing the hydrolysis and polishing rate of the coating. This allows vessels to operate with reduced fuel consumption over longer periods, using less biocide than conventional coatings. FASTAR’s technical advancements enable customers to apply the coating as easily as, or even more easily than, with conventional paints using their existing application equipment. In addition, customers can benefit from long-term reductions in fuel oil consumption, resulting in economic savings and reduced CO₂ emissions. Furthermore, by the integration of Nippon Paint Marine’s proven HydroSmoothXT™ technology, we provide solutions that further reduce hull friction and maximize fuel saving effects.

In essence, FASTAR was engineered to pursue all three key aspects: environmental friendliness, economic benefits for customers, and practical compatibility with existing application facilities, in line with the pressing global shift toward carbon neutrality and increasingly stringent environmental regulations. FASTAR reflects Nippon Paint Marine’s commitment to long-term innovation, even if that means a decade of development, and represents a groundbreaking advancement that is redefining industry standards. We are proud to confidently recommend FASTAR as the coating of choice for today’s needs.

Q2.How did customer feedback and input from frontline teams help drive the development of FASTAR?

A2.FASTAR’s true value lies in its direct response to the real-world challenges faced by customers operating in harsh marine environments. Its development was deeply rooted in continuous feedback from customers as well as from our sales and technical service teams, ensuring that practical needs were fully incorporated into the final product.

At Nippon Paint Marine, our R&D environment is uniquely characterized by its close physical and psychological proximity to both the sales and technical service divisions. This tight-knit structure allows the R&D team to receive not only technically rigorous improvement requests from a customer-first perspective but also a continual flow of practical insights from the on-site experiences. Requests such as “customers need shorter application timelines,” “flawless application is needed even under adverse weather conditions,” and “we must provide a robust coating that can withstand rough berthing” are part of our daily dialogue. Each R&D engineer takes these requests to heart, approaching them not as external demands but as personal challenges to solve.

We R&D engineers also frequently visit customer sites to hear directly from customers and professional painters. These on-site insights, combined with repeated field trials and extensive validation data, are incorporated into the product design through an iterative process of improvement. As a result of these efforts, FASTAR is now offered in four primary grades, enabling us to provide tailored solutions that meet a wide range of operational requirements. To further strengthen trust, we R&D engineers often accompany the sales team on customer visits, where we personally provide explanations of technical features and product benefits. Meanwhile, our technical service team work closely with customers on-site, providing comprehensive support¬from recommending application methods tailored to each situation, to inspecting the finished conditions and offering aftercare. I believe that our strong commitment to a frontline-driven approach, our open organizational culture that fosters spontaneous cross-functional collaboration, and our flexible development framework that actively transfers technical expertise to the next generation of R&D engineers through daily hands-on experience together form the foundation for both our technological advancement—exemplified by FASTAR—and our high level of customer satisfaction.

Q3.What is Nippon Paint Marine’s vision for the future of its technological development?

A3.At Nippon Paint Marine, our commitment extends beyond addressing today’s challenges; we are continuously looking ahead to anticipate the evolving needs of the maritime industry and broader society for a decade into the future. Guided by this long-term perspective, we dedicate ourselves daily to the advancement of marine coatings and antifouling technologies. Once applied, these coatings must withstand years of exposure to harsh marine environments that place significant stress on both the vessel’s hull and the coatings. To remain ahead of the curve, we must respond swiftly to yet unseen future challenges such as rising ocean temperatures due to global warming, the risk of new marine organisms emerging and causing fouling, and the tightening of international environmental regulations. Our response lies in further evolving our technologies accordingly.

A breakthrough achieved through nano domain technology paved the way in the development of FASTAR, and we are already envisioning new ideas to further advance this innovation. We view this as a fundamental technology that can address future regulatory changes and climate-related impacts. We are also continuously carrying out research and development on state-of-the-art technologies, with an eye toward the day they will become key pillars of our business in the future.

Nippon Paint Marine has a long track record of industry leadership through both innovation and practical implementation, exemplified by our world-first commercialization of tin-free self-polishing antifouling paint. In pursuit of carbon neutrality and a sustainable society, we remain fully committed to the development of marine coatings and antifouling technologies that deliver superior environmental performance, excellent workability, and outstanding economic value. Guided by a healthy sense of future-oriented risk awareness and an insatiable intellectual appetite as R&D engineer, the entire Nippon Paint Marine team remains committed to working closely with customers and frontline staffs to establish new standards in marine coatings.

Sales Representative Insights

Tomoya Taniguchi

Nippon Paint Marine Coatings Co., Ltd.

Tokyo

Sales Office, East Japan Sales Department, Sales Division

Q1.How do you, as a sales representative, address the challenges faced by the maritime shipping industry and customer needs, and how do you propose FASTAR to your customers?

A1.In recent years, the maritime shipping industry has been under increasing pressure to meet environmental regulations and enhance fuel efficiency. On the operational front, ship operators are particularly focused on reducing fuel costs, driving strong demand for hull coatings that minimize frictional resistance and lower fuel consumption and operating expenses. At the same time, shipowners are prioritizing solutions that help preserve the long-term value of their vessels, extend hull lifespan, and manage total cost of ownership.

FASTAR represents Nippon Paint Marine’s strategic response to the evolving needs of both ship operators and owners. Engineered for efficiency, it delivers exceptional antifouling performance with a thinner coating layer, enabling faster application and reduced dry-dock time. Beyond operational benefits, FASTAR also supports global environmental goals by helping to lower environmental impact and curb the spread of invasive marine species through effective biofouling control.

When proposing FASTAR to customers, a key challenge is helping them understand the new value it brings, specifically, its ability to deliver reliable performance with a thinner coating compared to conventional products. Since FASTAR represents a technological advancement, some customers may initially be hesitant or uncertain about making the transition. To address this, I work closely with our technical team to provide detailed explanations of the product’s features and benefits. I often recommend a trial application on a single vessel. This allows customers to evaluate FASTAR’s performance in real-world conditions. As successful results are shared and a track record is established, customers gain confidence in the product, often leading to wider adoption across their fleets.

Q2.How do you collaborate with the technical team and other relevant departments to overcome challenges encountered in the sales process?

A2.One of Nippon Paint Marine’s key strengths lies in our ability to function as a cohesive team, with sales, R&D, technical service , and marketing departments working in close coordination. This cross-functional collaboration is crucial, not only for providing in-depth technical explanations that go beyond what the sales team alone can offer, but also for establishing trust with customers on the ground. Since FASTAR introduces new value and departs from conventional approaches, it’s particularly important to complement theoretical explanations with real-world data and feedback from actual vessel applications. This integrated, team-based approach helps ensure that customers fully understand and appreciate the benefits of FASTAR.

For example, once a customer has confirmed FASTAR’s performance through an initial application on a vessel, our technical service team conducts on-site inspections using drones and underwater cameras to assess the hull’s condition while the vessel is in operation, as well as visual examinations during dry-docking. We then compile detailed reports covering coating thickness and the degree of hull fouling, which are shared with the customer to provide clear, data-driven insights. Additionally, our marketing team prepares analytical materials evaluating fuel efficiency and overall performance, ensuring that our proposals and reports are precisely tailored to each customer’s specific requirements.

Many of our customers conduct their own independent analyses of coating performance, making it essential for us to have a robust support framework that delivers clear, data-driven explanations. While the sales team often takes the lead in recommending paints and coating specifications, we rely heavily on the technical team’s expertise, particularly for evaluating real-world performance and resolving any challenges that arise. This open, collaborative culture enables us to respond sincerely and proactively, even to the most demanding customer requirements. As a result, we’re not only able to offer tailored, value-added solutions but also build lasting customer relationships that often lead to repeat orders beyond the initial trial.

Q3.Looking ahead, how do you see yourself contributing to the future of the maritime shipping industry and supporting your customers’ evolving needs?

A3.When FASTAR was first launched, it was sometimes difficult to clearly differentiate its advantages from those of competing products. However, as the product evolved and we gained more real-world application experience, customer feedback became increasingly positive. Many began noting that “performance has become more consistent” and “overall operating costs have gone down.” In fact, some customers who initially applied FASTAR to a single vessel were so impressed by its in-service performance and the quality of our after-sales support that they ultimately decided to convert their entire fleet to FASTAR.

This growing track record has not only enhanced the recognition and credibility of FASTAR in the market but has also strengthened my confidence as a sales representative in promoting its broader adoption. Looking ahead, I aspire to help address global challenges in the maritime shipping industry and to become a well-rounded generalist, with experience spanning both the newbuilding sector and international markets. As social expectations for environmental responsibility and CO2 reduction continue to rise, I am committed to remaining at the forefront of sales, helping to shape new industry standards through FASTAR and other next-generation technologies.

User Feedback

NS United Kaiun Kaisha, Ltd.

Ship Maintenance Team

Ship Management Group

Q1.In light of the global tightening of environmental regulations and the increasing emphasis on fuel efficiency, what are your perspectives, as a marine transportation company, on the significance and future outlook of antifouling coatings?

A1.In recent years, as international environmental regulations have tightened and the focus on fuel efficiency and energy-saving operations has grown, the choice of antifouling coatings has become a critical priority, both for reducing operating costs and for minimizing our environmental footprint. While measures such as hull form optimization and propeller upgrades are effective, they typically require substantial investment and extended downtime. By contrast, the adoption of advanced antifouling coatings offers a more practical and cost-efficient solution, enabling quicker implementation and the realization of immediate performance benefits. By selecting advanced high-performance antifouling coatings, we are able to significantly suppress hull fouling, reduce frictional resistance, and realize sustained fuel savings. Given these tangible advantages, we have placed particular emphasis on the evaluation and application of high-performance antifouling coatings as one of the most effective solutions available to us.

Q2.Among the wide range of antifouling coatings available in the market, what key considerations led your company to adopt FASTAR?

A2.In evaluating antifouling coatings, we placed the highest priority on long-term performance, ease of maintenance following application, and overall cost-effectiveness. When compared with conventional alternatives, FASTAR stood out for its advanced coating film technology, which not only delivers superior antifouling performance but also streamlines the application process while ensuring excellent cost performance in line with our operational requirements.

Our decision was further reinforced by the comprehensive support provided by Nippon Paint Marine. Their sales representative offered clear and detailed explanations of FASTAR’s technical advantages and cost benefits, while presenting well-structured proposals and proactive guidance. This combination of product superiority and strong professional support was decisive in our choice to adopt FASTAR.

Q3.How would you evaluate the performance of FASTAR since its adoption, and what are your expectations for Nippon Paint Marine going forward?

A3.Since adopting FASTAR, we have been able to visually confirm its superior antifouling performance, with the coating condition remaining noticeably better than with previous products. Nippon Paint Marine is currently conducting comparative assessments of performance before and after FASTAR’s adoption, and we look forward to reviewing the findings of this verification.

Looking ahead, we hope Nippon Paint Marine will continue to carry out regular onboard inspections, provide ongoing guidance to our crew, and further leverage technologies such as underwater drones to monitor the condition of antifouling coatings. At the same time, we expect continued improvements in cost competitiveness, along with more advanced technical proposals and user-focused support to meet increasingly strict environmental regulations and the evolving demands of marine operations.

- Column: About NS United Kaiun Kaisha, Ltd.

-

Established in 1950 and headquartered in Chiyoda-ku, Tokyo, NS United Kaiun Kaisha, Ltd. is a leading Japanese marine transportation company operating primarily in international cargo shipping. The company has built a strong competitive position in bulk cargo transport, particularly in the movement of steel raw materials and energy resources.

NS United Kaiun places the highest priority on safety and reliability, supported by a robust management framework that ensures safe vessel operations through close coordination between its Safety Management Group and Vessel Management Group. The company is also deeply committed to environmental stewardship, proactively embracing advanced technologies while striving for zero maritime accidents through rigorous safety measures in vessel operations.

Guided by integrity at the core of its mission, NS United Kaiun continues to contribute to society through the provision of high-quality marine transportation services.