Industrial plants and their facilities, as well as bridge structures near coastlines, are continuously exposed to saline air, moisture, and saltwater. Ensuring long-term durability of these assets demands coatings with superior resistance to salt exposure. To address the demand for extended asset life and reduced lifecycle costs, we developed Danziora: a cutting-edge anti-rust coating that delivers superior protection against salt-induced corrosion while streamlining the application process.

Protecting Structures from Salt Damage: An Innovative, Counterintuitive Approach

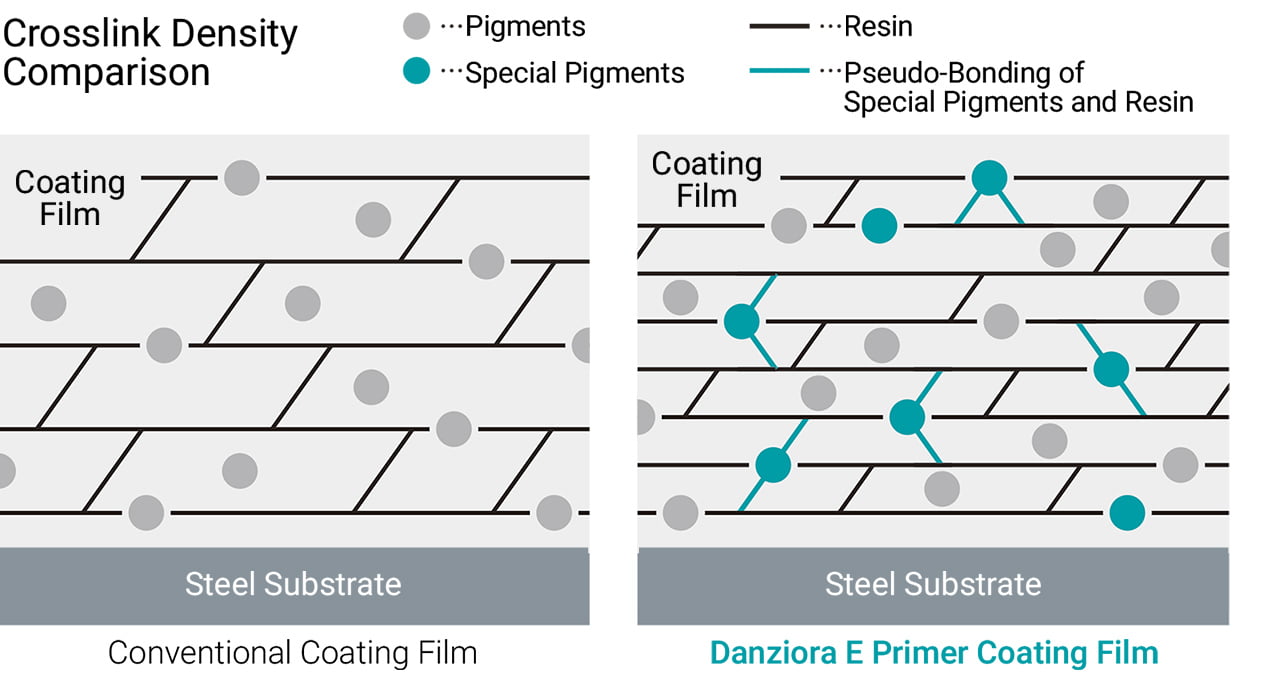

The name Danziora is derived from the Japanese words for “blocking” (Dan) and “salt” (Zio), reflecting our focus on safeguarding buildings and equipment exposed to harsh, salt-laden environments.Metal corrosion is primarily driven by three factors: salt, oxygen, and moisture. Preventing corrosion therefore requires blocking these elements from reaching the metal surface: most commonly through the use of protective coatings. However, conventional coatings cannot completely prevent water vapor penetration due to inherent limitations in typical paint-film structures. Danziora applies an innovative and seemingly counterintuitive solution. Instead of relying solely on moisture repellence, its specialized formulation incorporates pigments that gradually dissolve when exposed to penetrating water vapor. As they dissolve, these pigments create a pseudo-bond with the resin, tightening the coating structure and further limiting the passage of salt and oxygen. In effect, Danziora turns moisture into a strengthening agent: reinforcing the protective barrier through a breakthrough mechanism developed by rethinking the fundamentals of anti-corrosion design.

Helping Reduce Application Time and Costs

Proper surface preparation is critical for ensuring uniform application and optimal coating performance. Standard practices, such as abrasive blasting or mechanical rust removal, are effective but can be difficult to implement when repainting bridges or factory and plant equipment. These structures often require strict adherence to fire safety regulations and work must be carried out in confined or hard-to-access areas. In many cases, coatings must still be applied even when a certain amount of rust remains on the surface. To meet these real-world challenges, we developed a coating that combines anti-corrosion protection with a rust-conversion function, enabling rapid surface stabilization even in the presence of residual rust. Seasonal factors also create practical constraints. Conventional primers may cure quickly in summer at room temperature, but drying times increase significantly in winter, especially in colder regions, leading to extended project schedules. Engineered for all-season use, Danziora’s formulation minimizes drying time between coats - whatever the season. Its chemistry minimizes drying time between coats regardless of temperature, and its excellent low-temperature curing capability allows it to dry even at –5°C. This enables smoother workflows, shorter application timelines, and meaningful reductions in overall project costs.

Adopted for the Nationally Designated Important Cultural Property, Waka-To Bridge

In salt-laden environments, protective coatings typically require a four-layer system - two primer coats, one intermediate coat, and one topcoat - to effectively block corrosion factors. Danziora E Primer delivers exceptional barrier performance, providing equal or superior protection to two conventional primer coats with only a single application. This innovation allows the primer layer, traditionally requiring a dry film thickness of 120 μm (1 μm = 1/1000 mm), to be reduced by half while maintaining high protective capability. Furthermore, increasing the thickness of the topcoat makes it possible to eliminate the intermediate coat entirely. The result is a thinner overall film, a simplified application process, shorter project timelines, reduced paint consumption, and lower environmental impact. In January 2025, Danziora was selected for repair work on the Waka-To Bridge in Kitakyushu City, a structure designated as a National Important Cultural Property. We will continue to actively promote this nationally recognized technology and expand its adoption in future infrastructure preservation projects.