Enriching Lives with Diverse Color Choices and Effortless Stain Care

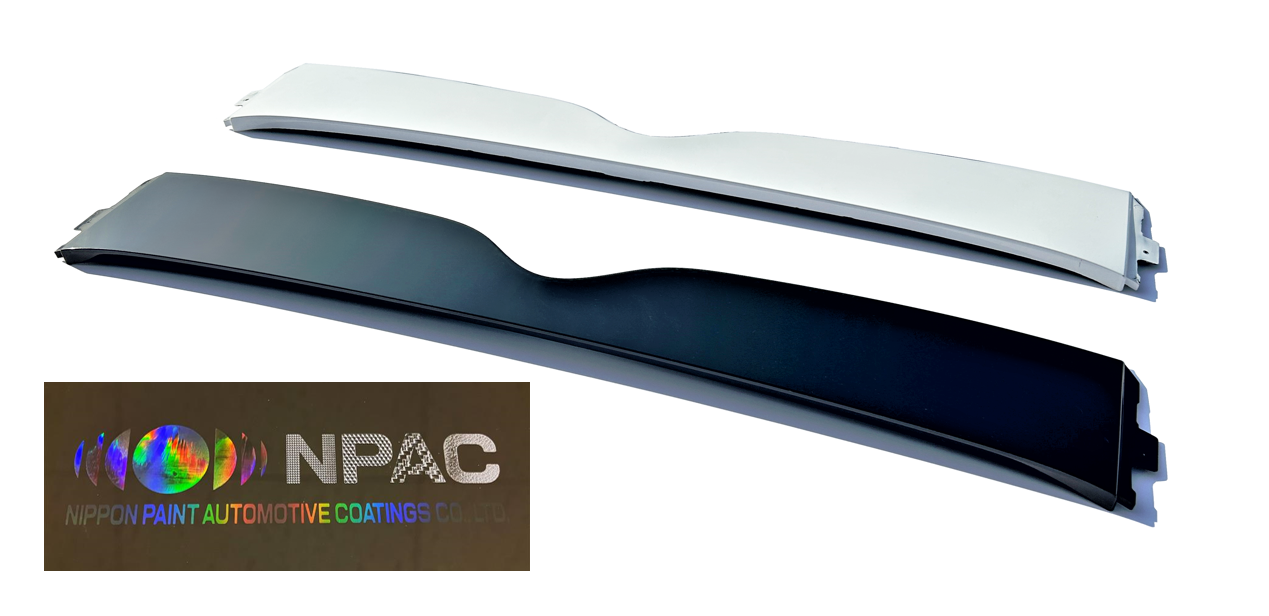

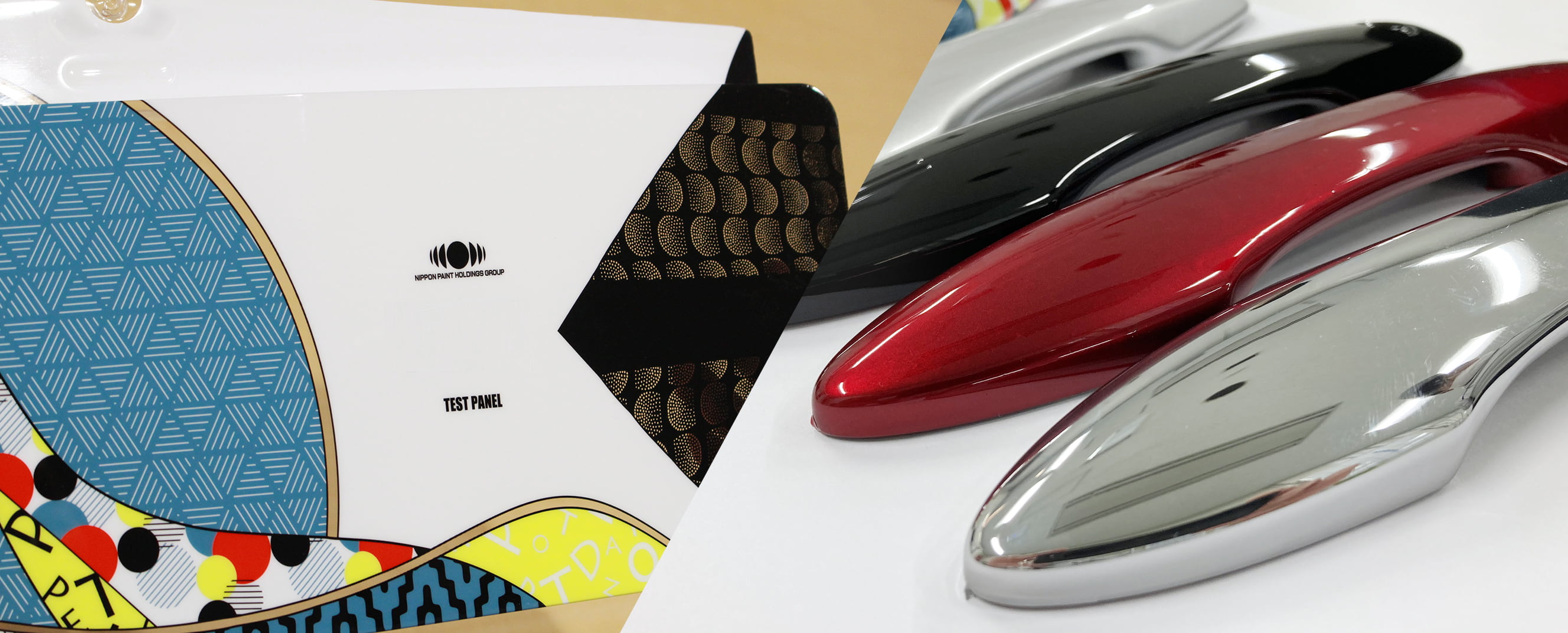

Range hoods are frequently exposed to high heat, making them susceptible to stubborn, dried-on grease stains. Powdux Kino 2 tackles this challenge with a unique formulation that blends a specialized silicone polymer and fluororesin into its polyester resin base. This creates a protective surface layer that actively repels oil, allowing even dried or persistent grease to be wiped away effortlessly. Beyond its exceptional stain resistance, Powdux Kino 2 offers a wide range of color options to suit modern kitchen preferences. As more people choose appliances that reflect their personal style, range hood coatings are now available not only in timeless shades like white and black but also in vibrant tones such as red, blue, and silver, combining practicality with aesthetic appeal.

Contributing to the Reduction of Steel Resource Loss

While most standard coatings can be applied in multiple layers without difficulty, oil-repellent coatings often present a challenge: applying a second layer can cause surface defects, such as dents where the new coat pushes aside the previous one. Powdux Kino 2 overcomes this issue with a unique formulation that combines strong oil-repellent properties with the ability to be repainted over dried coatings. In cases where surface flaws occur during finishing, such as dust particles becoming trapped, the affected area can be polished and the entire surface recoated without complications. Without this capability, the steel substrate would need to be discarded. By enabling seamless recoating, Powdux Kino 2 helps minimize material waste and contributes to reducing steel resource losses.

Reducing Environmental Impact Through Enhanced Durability

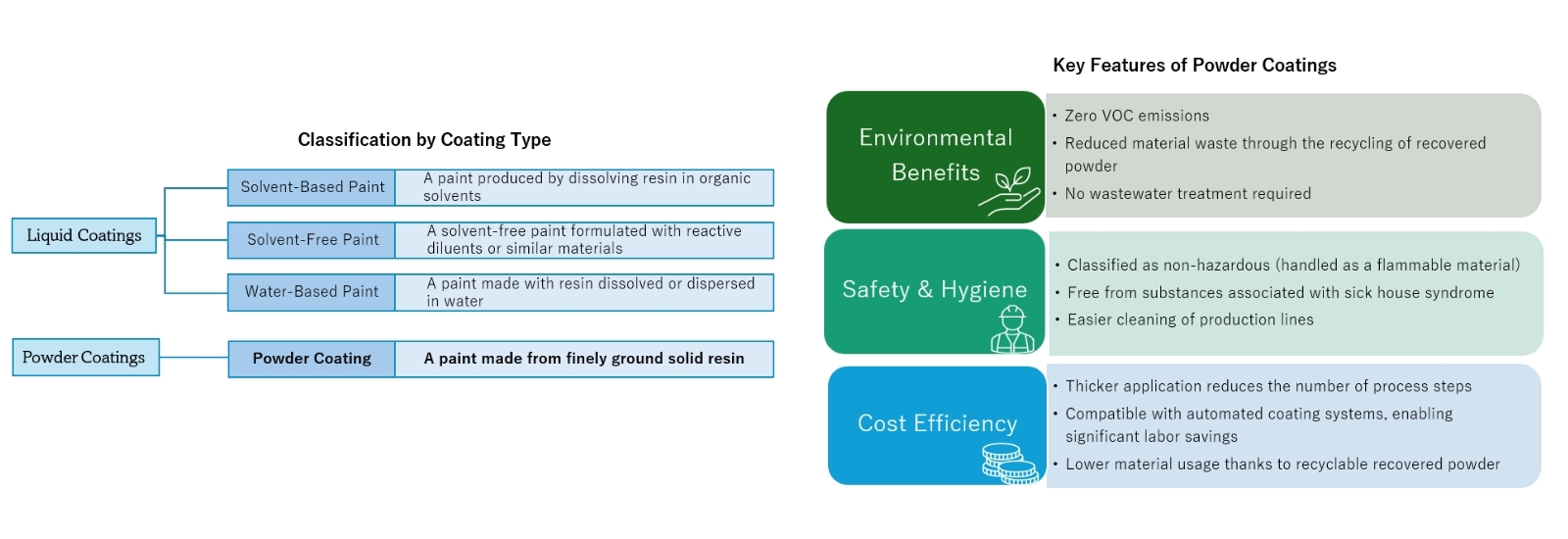

A key advantage of Powdux Kino 2 is that it is a powder coating, making it an environmentally conscious choice. Unlike liquid coatings, which emit higher levels of VOCs (Volatile Organic Compounds) and require expert skill to apply evenly, powder coatings offer a cleaner, more sustainable solution. Over time, many manufacturers have transitioned from liquid coatings to powder coatings to reduce environmental impact while improving application efficiency. In addition to being eco-friendly, powder coatings also provide superior durability. While liquid paints typically form a film 20–40μm thick (1μm = 1/1000mm), powder coatings create a robust 50–100μm layer in a single application. The result is a stronger, more resilient finish that extends the lifespan of range hoods while contributing to sustainability goals.

Contact for Oil-Repellent Coatings:

・Nippon Paint Industrial Coatings Co., Ltd. Click here to contact us.

Behind the Scenes