- Research and Development

- 2020.09.27

Long-term anticorrosion technology by visualizing the film thickness

The self-indicating (SI) function, which visualizes the coating film thickness, ensures the appropriate coating film thickness and helps the coating film demonstrate anticorrosion performance over the long term.

What is long-term anticorrosion technology by visualizing the film thickness?

The service life of coating films formed by epoxy paints, which are widely used as anticorrosion paints for vessels, depends largely on two conditions. One is whether the specified film thickness is ensured, and the other is whether the coating film is uniform. Coating engineers must be experienced and highly skilled to ensure that the specified film thickness is uniform. Because ship bottoms have a large area, part of the surface is likely to have inadequate film thickness and may serve as the starting point of corrosion.

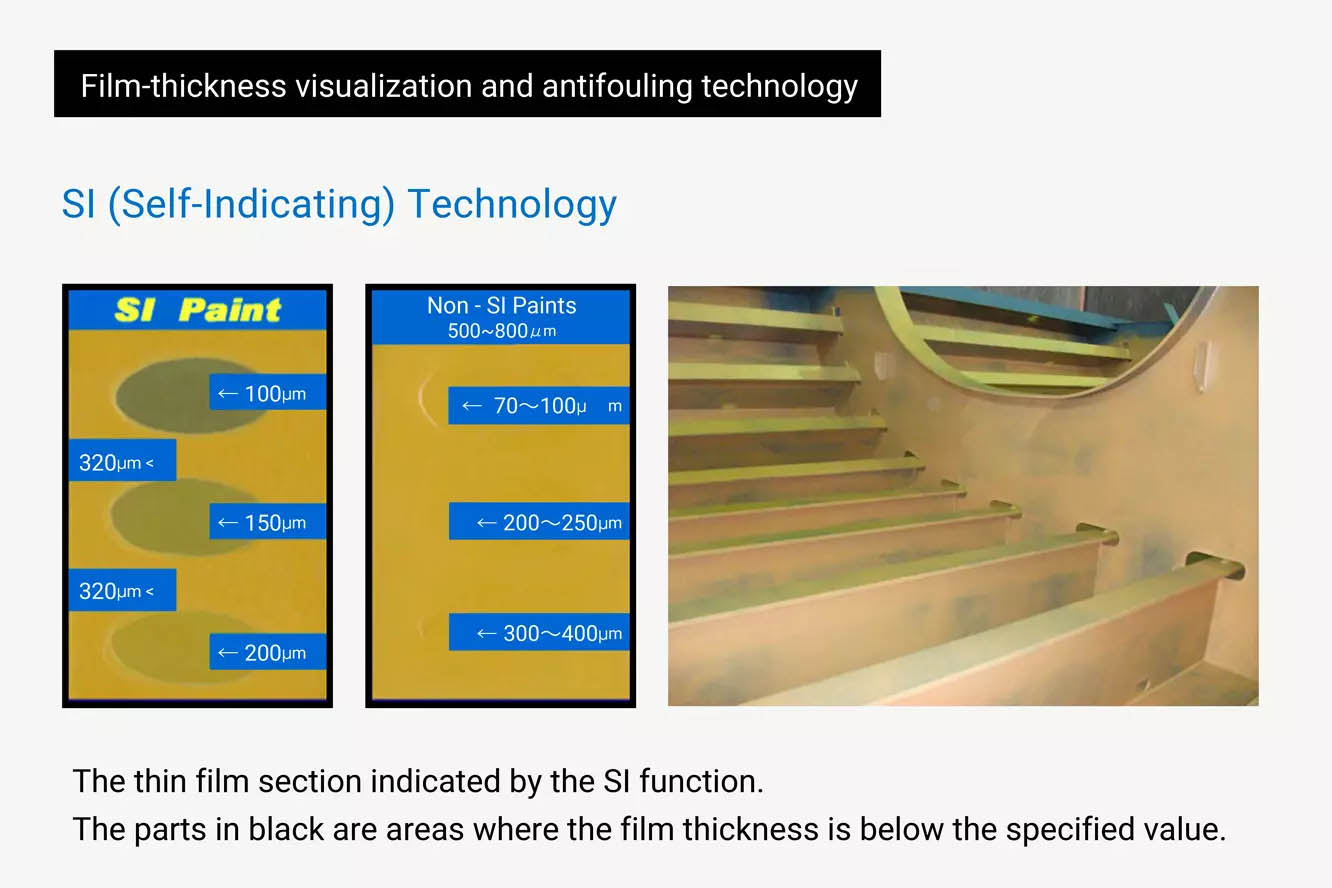

SI (self-indicating) refers to a function to keep a substrate whose coating film surface is below the specified thickness visible. SI is characteristic in that the film thickness can be assessed two-dimensionally (not one-dimensionally) and that the substrate visibility can be checked during and after coating. The characteristics enable coating engineers to determine whether the specified film thickness is attained during coating based on visual assessment and to visually spot areas whose film thickness is inadequate, making it possible to reliably prevent rust development caused by inadequate film thickness.

What are the key features of this technology?

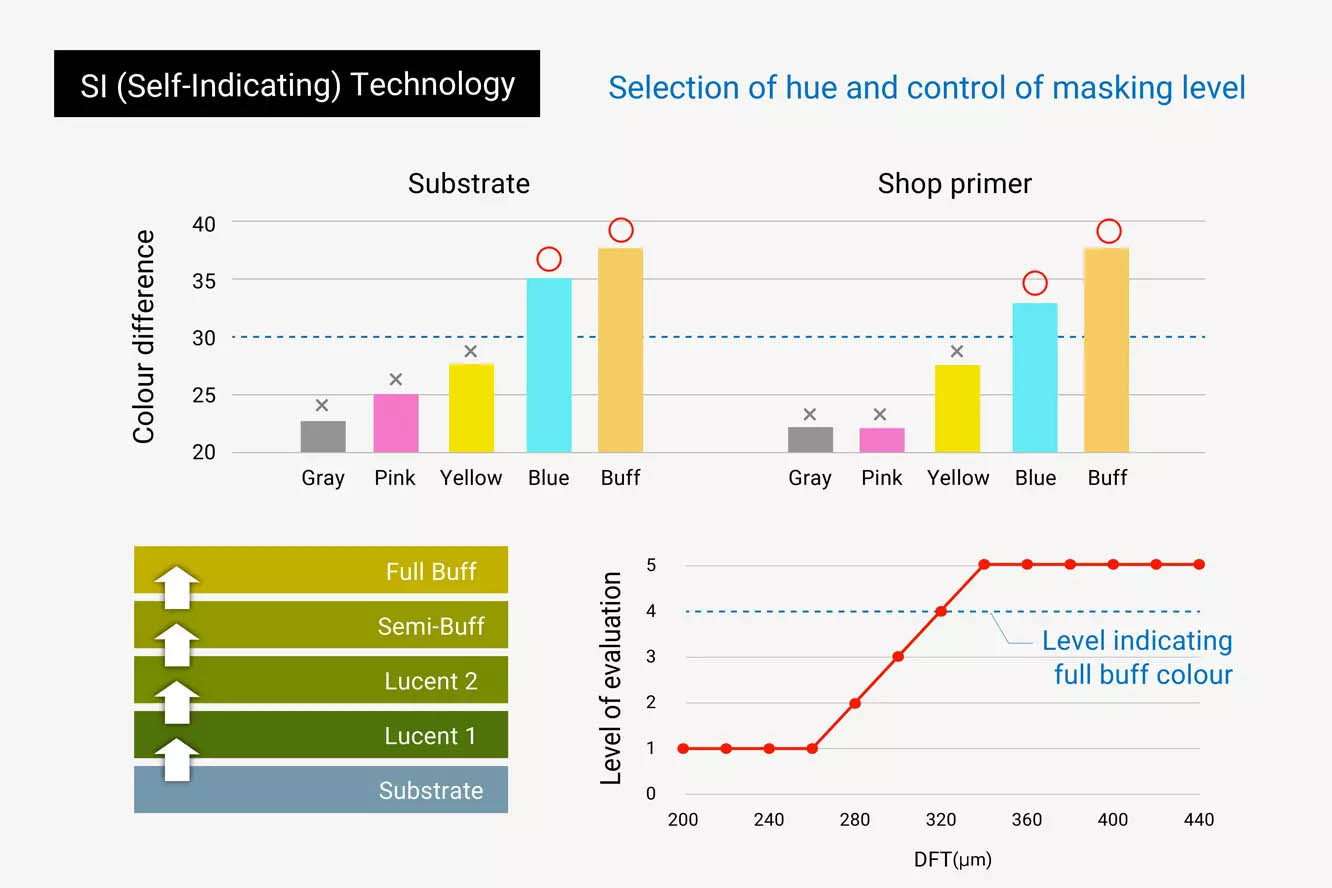

The key point of this technology is to select the most suitable color for SI (self-indicating) technology. Based on an investigation of the tone difference and hiding power, buff (tan) and blue were found to be suitable. Special pigments with various opacities are used depending on the coating film thickness to flexibly control SI, enabling application to various areas of different film thickness specifications. The viscosity and curing of paints are controlled by the mixture adjustment of the paint components to suppress the coating film defects, such as pinholes and cracks, and thereby attain stronger and more dense coating films. The technology enables visual inspection to ensure the film thickness and forms strong coating films to meet the international anticorrosion standard for ballast tanks, protecting many vessels from corrosion.

Contribution to solving social issues

Protection of metals from corrosion is a common issue in all fields around the world. The losses attributed to corrosion-related damage to marine transport vessels under construction or in operation are estimated at about US$50 to 80 billion, which is about 3% of global GDP. According to some statistics, corrosion accounts for 90% of vessel failures. Coating is one of the most effective solutions to prevent corrosion. This SI function makes it easy for any coating engineer to ensure the specified film thickness. It contributes to improving the coating film quality and streamlining the construction process. The SI function dramatically improves the anticorrosion effect during operation compared to that of conventional coating systems. Nippon Paint Marine Coatings contributes to protecting vessels, which are part of the social infrastructure, by supplying SI paints that demonstrate reliable anticorrosion performance.