Creation of sustainable products will drive long-term business success

Sustainability of our products

We believe that sustainability is a crucial element for our group’s products to benefit society and drive the

long-term success of our businesses.

We define sustainable products and technologies by aligning with the United Nations

Sustainable Development Goals (SDGs) and adopting a portfolio sustainability assessment (PSA)

process to enable identification of sustainable products. This encompasses a systematic

approach that includes main lifecycle stages of a product: Product feedstock, Production,

Applications and End of life. At each of these stages, we evaluate how our paint and coatings

products outperform market products by mapping specific SDG targets to their attributes.

In the production phase, the key evaluation points of products are production efficiency, raw materials, logistics,

packaging. In the use phase, the key evaluation points are reduction of energy and material consumptions and

emissions of chemical substances, along with the support to customers and consumers by reducing the toxicity of

chemical substances. In the service phase, the key evaluation points are useful lives of products, application to

green technology, contribution to health and well-being, and end-of-life treatment.

To support these sustainability activities, we developed the "Sustainability Scoreboard (scoring system)." This is

now incorporated into the "NPSI" system used by most partner companies in the Japan Group and NIPSEA Group. In 2024,

63% of new product sales from both the NIPSEA Group and Japan Group were newly developed sustainable products.

We also developed the Green Design Review, and have introduced it into the management system for Research and

Development projects at both the Japan Group and NIPSEA Group. In 2024, within the project portfolio of the Japan

Group and NIPSEA Group, 52% of R&D expenses were used to create products with sustainability advantage in accordance

with the principles of the Green Design Review.

Sustainable product data*

| New Product Sales Index (NPSI)

|

|

| Sustainable product ratio of the new product sales |

|

| Sustainable product development project ratio in R&D expenses |

|

*NIPSEA Group and Japan Group data

Results of sustainability products

Metalshield Rust Defence

DuluxGroup has introduced a new water-based Metalshield Rust Defence topcoat and a water-based

Metalshield Rust Defence Primer to replace the solvent based premium range.

The new water-based formula simplifies the steps to metal protection without compromising on performance

against rust and corrosion.

Intergrain Ultradeck Timber Oil

DuluxGoup's Cabot's business division has doubled down its

effort on developing category-leading water-based solutions that maintain, transform and protect timber.

Intergrain Ultradeck Timber Oil was relaunched in 2023 with best-in-class durability that lasts 3 times

longer than traditional oil-based coatings. This focus is generating an improvement in water-based

technology sales, and we're effectively transitioning the market to solutions that produce lower

lifecycle GHG emissions than traditional oil based decking oils.

EVEREST®

EVEREST® is a complete line of ultra-premium,

low-odor, Zero-VOC, self-priming, 100% acrylic paints ideal for use on high-end residential and

commercial projects. They apply easily and feature exceptional hide, superior scrub resistance,

washability and adhesion. EVEREST is the market-leading zero-VOC product made without the use of

chemicals of concern, such as ethylene glycol and APEO surfactants. Its favorable EHS profile makes it

ideal for use in consumers’ homes. We recently completed a generational product improvement project

targeting enhancement in washability, scuff resistance, and burnish resistance, allowing for longer

performance life.

Dulux envirO₂™

Dulux envirO2™ is a premium low odour, low VOC acrylic paint that delivers superior performance.

In 2022, the Dulux business achieved 50% recycled content in packaging for the envirO2™ range.

Dulux envirO2™ is also the only major Australian paint brand with a Global GreenTag™ certification.

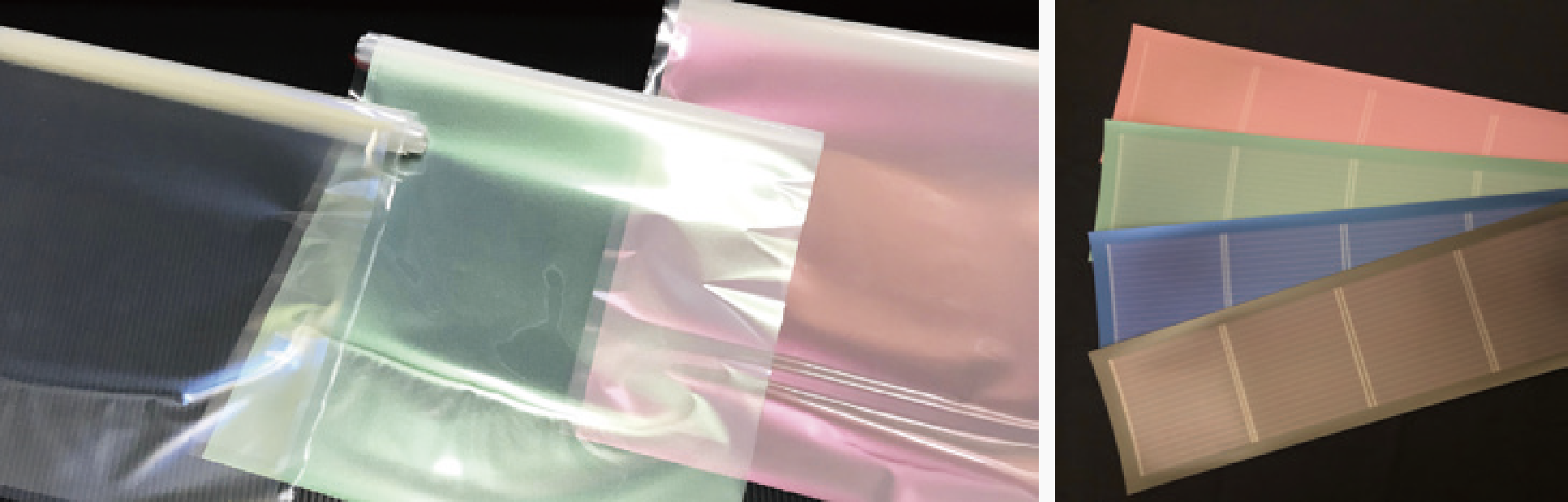

Decorative films

Nippon Paint Group is actively developing products for

photovoltaic generation systems and lithium-ion batteries (LIBs) to contribute to a sustainable,

low-carbon society. Toyota Motor Corporation and Nippon Paint Automotive Coatings have jointly developed

decorative films for photovoltaic modules, offering greater flexibility in design and color.

High adhesion primer

Nippon Paint Surf Chemicals (NPSU) has developed a

high-adhesion primer, SURFCOAT NR-Z, specifically designed for pouch-type lithium-ion battery (LIB)

packaging. This new product ensures excellent adhesion even after prolonged immersion in electrolytes.

Low Temperature, Fast Curing “ACECRON 130”

Nippon Paint China’s ACECRON series is an innovative low-temperature curing electrocoat platform

designed to enhance ESG performance in the automotive industry. This product caters to the market demand

for energyefficient and eco-friendly coatings, particularly suitable for components requiring low

temperature drying and complex assemblies. Today, “ACECRON 130” has been recognized for its ability to

cure at 130°C without lead or tin, offering a significant reduction in energy consumption and CO2

emissions compared to traditional curing processes. The product demonstrates excellent corrosion

resistance and coating stability, maintaining high performance at lower temperatures.

Low-carbon binder

Cement is a widely used raw material in substrate products, but

it releases a large amount of carbon dioxide during production. In order to reduce carbon emissions, we

are developing a low-carbon binder to replace cement. In 2024, we used self-developed low-carbon binder

to replace 40% -50% of cement in putties, and the performance after replacement is close to the original

formulations, while carbon emissions can be reduced by more than 30%. We are currently in double test of

the formulations and hope to launch new putty products with lower carbon emissions by 2025.

Low temperature Fast Cure General primer for appliance, “NPEP FLEKS 760N”

Launched as "NPEP FLEKS 760N" in Q2 2024, this low-temperature

fast-curing primer reduces drying oven temperatures, saving up to 28% energy and lowering CO2 emissions.

It is compatible with Cr-free pretreatment substrates and offers high adhesion, corrosion resistance,

and excellent workability, ensuring stability during heat storage. For the integrated product series of

primers for home appliances, it will also contribute to improving paint production efficiency.

Recognized with the Rong Ge-Technology Innovation Award in May 2024, it supports home appliance

companies in reducing costs and environmental impact while improving productivity.

Low temperature curing PD (HAA)

With powder coating, CO2 emissions from the baking process are greater than from the paint manufacturing

process, so lowering the baking temperature makes a significant contribution to reducing CO2 emissions.

HAA curing powder paints have superior low-temperature curing properties compared to the BI curing paint

that is widely used in Japan, and by applying HAA products, the baking temperature can be lowered from

180℃ to 160℃, reducing CO2 emissions from the baking process by 11.3%.

In addition, our HAA products have excellent paint workability with electrostatic charge improvement

technology, and are accelerating their replacement by manufacturers of steel furniture, etc.