- Global

- 2021.04.06

Next-generation Industry-first Nanotechnology-based Hydrolysis Antifouling Paint “FASTAR”

Nippon Paint Marine Coatings Co., Ltd., a group company of Nippon Paint Holdings Co., Ltd. engaged in the production of marine coatings, has launched FASTAR, a proprietary antifouling coating that incorporates for the first time a hydrophilic and hydrophobic nanodomain structure using unique nanotechnology in January 2021.

Developed with the concept of “Faster and More Eco-friendly,” the ship bottom antifouling paint “FASTAR” is designed as an eco-friendly marine coating that improves the operation of vessels by minimizing the impact of seawater temperature, ship speed, and other factors affecting the efficiency and environmental properties of vessels.

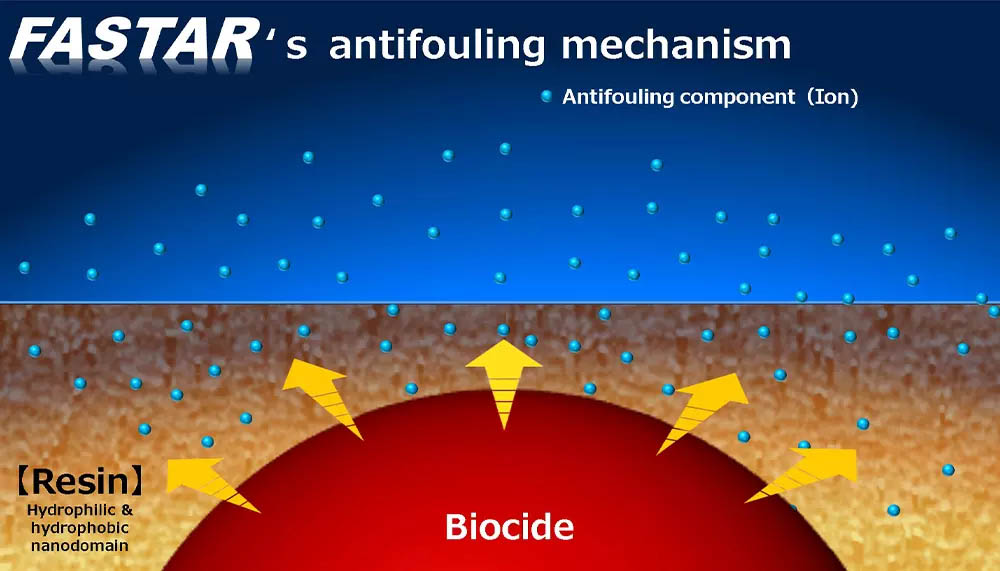

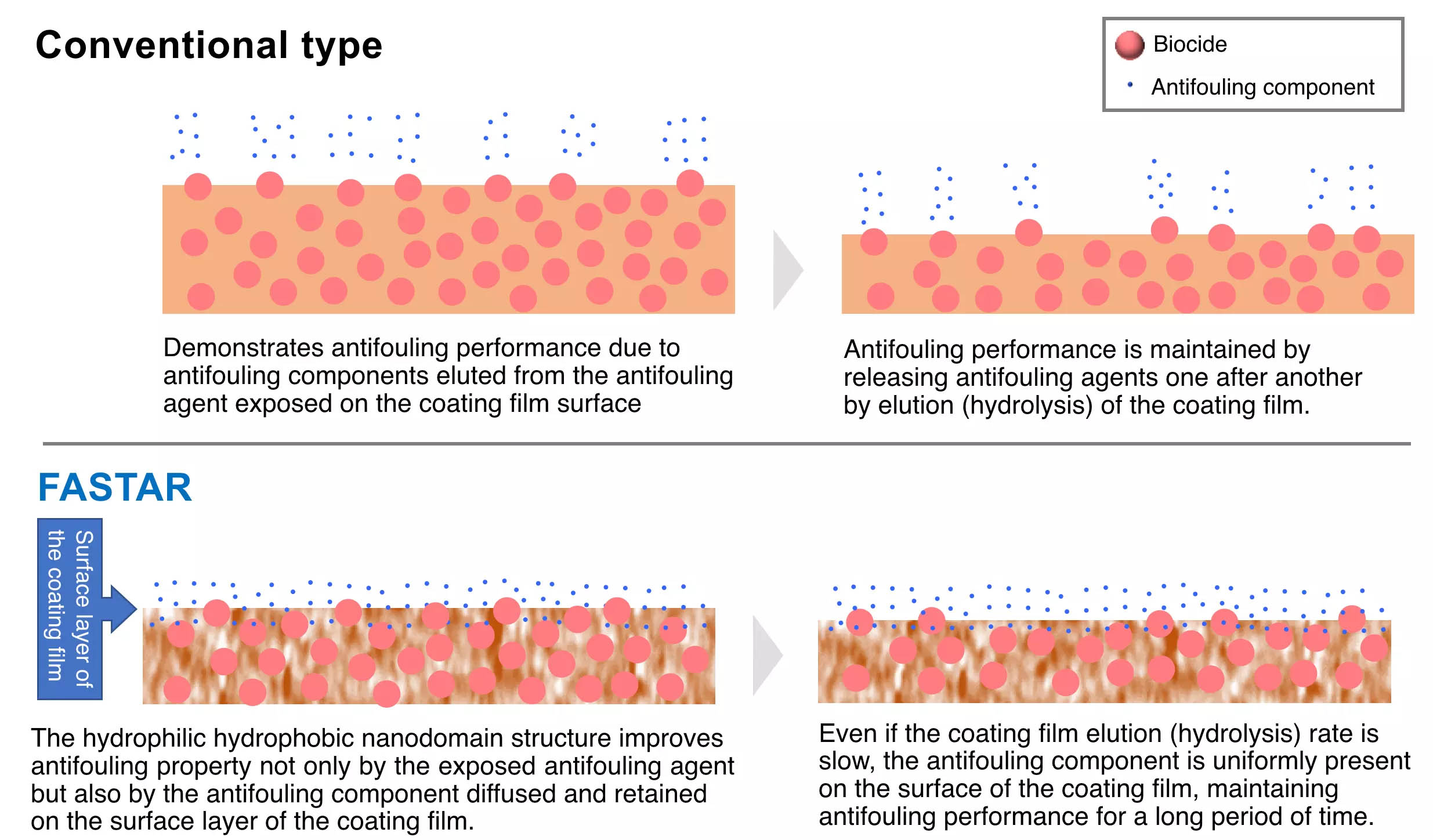

FASTAR is a low-friction, self-polishing antifouling coating that uses a highly advanced antifouling technology. FASTAR has a unique hydrophilic and hydrophobic nanodomain structure in the coating film, which provides excellent antifouling performance by uniformly and efficiently eluting antifouling components from the surface of the film.

Following pictures show the difference between conventional products and FASTAR on the surface of the coating film.

FASTAR incorporating this technology contributes to safety and health and environmental protection.

- Reduces the load on the marine environment.

The adoption of resin with nanodomain technology helps to diffuse and maintain antifouling components on the surface of the coating film. As a result, elution of antifouling agents is over 50% lower than in conventional products. - Reduces the painting process steps.

The thickness of the coating film can be reduced by approximately 30% compared to the Company's conventional products. This reduces the number of paint coatings and shortens the work period by approximately 37%. - Delivers economic benefits by reducing fuel consumption and CO2 emissions.

Nippon Paint Marine Coating’s unique water trapping technology, which was inspired by the skin of tuna to reduce friction resistance between the hull and seawater, is used in two of the lineup products to reduce the fuel consumption of vessels by approximately 8%.

In recent years, seawater temperatures have changed dramatically due to global warming, and ship operations have been varied to comply with changes in the shipping market. The changes in the maritime transport market are forcing the operators of vessels to meet a broader range of needs. In addition, vessel operations must take steps to prevent pollution of seawater and reduce CO2 emissions. We will continue to tackle environmental issues and develop antifouling paint products that can contribute to efficient and environmentally responsible vessel operations.