Management of chemical substances

Our products comply with the Hazardous Chemical Substance Regulation

Chemical substance management

In 2021, Japan Group launched the “Green 30” chemicals management system to manage

Chemicals of Concern (CoC) based on regulations or treaties such as REACH regulations in EU,

TSCA in the USA and CSCL in Japan. We classify chemical risks into three categories (Rank A,

Rank B, Rank C)*1 according to the laws and regulations in the countries where we operate.

Japan Group started using this system in 2021 and the system is being expanded to our partner

companies outside Japan.

Alkylphenol ethoxylates (APEs) are mainly used for surfactants and include the subcategory of

nonylphenol ethoxylates (NPEO/NPE). Nonylphenols (NP), raw materials for NPE, are regulated by

REACH and TSCA. Nippon Paint Group has been steadily phasing out APEs-containing surfactants.

In addition, we have been replacing UV absorbers such as UV-328 and UV-327, and in Japan

Group, the phase-out of UV-328 was completed by the end of 2023. Japan Group is also reducing

chlorinated paraffins, including other POPs, medium-chain chlorinated paraffins. Within China, we

have implemented initiatives to reduce CMR substances*2, concentrating on product

accountability, strategic approaches, and successful outcomes to promote sustainability.

This includes decorative business and industrial business, like waterproof and highperformance

or substrate sectors, where all CMR substances have been eliminated and will

not be used in the future.

|

Chlorinated paraffins usage (2019=100) |

UV-328 usage (2019=100) |

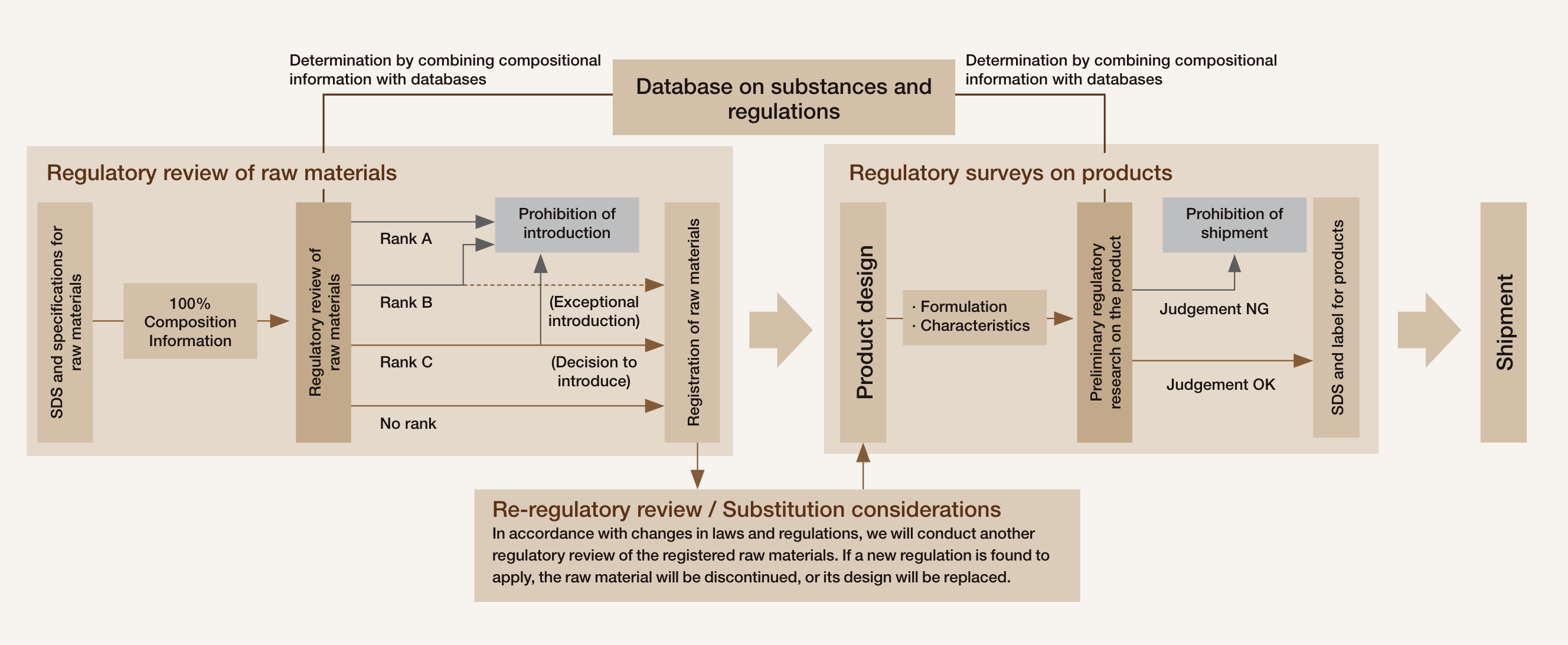

Chemical substance management flow

*1 The definitions of categories

Rank A (Prohibited): Prohibition of introduction

Rank B (Restricted for new introduction): Prohibition of new introduction with some exceptions

Rank C (Avoid new introduction): Decide whether or not to introduce based on regulatory trends, environmental

impact, and the business environment

No rank: No impact on raw material introduction

*2 Carcinogenic, mutagenic or toxic for reproduction

Initiative As of May 31, 2025

DuluxGroup

The DuluxGroup Product Stewardship program aims to manage risks and increase the sustainability of our products throughout their lifecycle, from raw material purchase through to disposal of used product and packaging. Each year, our businesses assess opportunities and develop action plans to improve the sustainability performance of products in priority areas, including:

- Consumer safety and product misuse

- Post-consumer waste

- Raw materials impacts, including chemical substance management

- Life cycle environmental impact and carbon footprint

- Packaging, labeling and safety data communication

- Distribution

Our business has a management program in place to reduce risks associated with chemicals in our products, including

those with potential for long-term health or environmental effects (chemicals of concern). We have developed group

position statements for 106 (98%) of the higher concern chemicals, and these detail how each chemical will be

managed to eliminate or reduce the risks (e.g. phase out, restrict use, establish additional controls, increase

research effort). In recent years, we have been working to phase-out alkylphenol ethoxylates (APEs) and non-aromatic

aliphatic fluorinated compounds. All PFAS variants listed on the Stockholm Convention are Prohibited above the

trigger concentration thresholds. We are also working to formulate from all known use of non-polymer forms of PFAS.

As PFAS are not always declared on safety data sheets, we are working with suppliers to identify any undeclared

PFASs in materials supplied so that these can be reviewed for phase out.

In the European businesses, the approach to management of chemicals of concern is aligned with the REACH regulations

with businesses monitoring emerging classification decisions and regulations and addressing in accordance with the

requirements and stipulated timeframes.

Implementation of our packaging recycled content roadmap continued in the Pacific region, with highlights including:

- Delivery of 30% recycled content in Selleys Point Works pails

- Progressing 50% recycled content in the 15 liter Dulux Professional, Hadrian and Berger Gold Label trade range with approximately 75% of these ranges to be transitioned by the end of 2025

- Implementing recycling of 30% post-consumer Dulux pail waste into Dulux NZ plastic paint packaging

- Continuing the transition to 60% recycled content in LDPE bags in our Yates business

Japan Group

In 2021, Japan Group launched the chemical substance management system named “Green 30,” in order to minimize the

impact on environment and human health. We developed this system to manage not only chemical substances to be

compliant with Japanese chemical regulations but also those of global concern with international treaties such as

REACH regulations. We classify the chemical risks in three categories according to the laws and regulations in the

countries where our business operates: prohibited, restricted for new introduction, and avoided for new

introduction. The system started in operation in Japan in 2021, and the practice is being introduced to our partner

companies outside Japan.

Alkylphenol ethoxylates (APEO) are surfactants and include a subcategory of nonylphenol ethoxylates (NPEO/NPE).

These types of nonylphenols (NPs) are being regulated by the EPA, REACH and CSCL. Nippon Paint Group has been

steadily phasing out APEO-containing surfactants. In 2021, we eliminated the use of the nonylphenol compounds in our

products in Europe and are working to eliminate them in Japan. We monitor trends in PFAS regulations in each

country, ensuring compliance with the PFAS regulations in each country for both domestic use and export.

Dunn-Edwards

In 2019, Dunn-Edwards successfully converted its entire portfolio to low-VOC, water-based products. Dunn-Edwards is

firmly committed to the over-arching green principle of eco-efficiency. We define “eco-efficiency” as the ability to

satisfy human needs in ways that minimize adverse impacts on energy and material resources, environmental quality

and human health and safety. For us, eco-efficiency means: “do more good,” by optimizing the performance of our

paint products, and “do less harm,” by reducing or avoiding the use of harmful ingredients. Other green principles

flow from the principle of eco-efficiency: resource conservation, energy efficiency, waste minimization, recycling,

emissions reduction, health and safety protection, and social responsibility. Consequently, our paint formulations

do not include – among other things – asbestos, benzene, cadmium and chromium pigments, chlorinated solvents,

dioxin, ethylene glycol, formaldehyde, lead, mercury, methylene chloride, or phthalates.

We plan on replacing our PFAS-containing resins and surfactants by the end of this year with some carry through of

existing materials into early 2026.